Dentists depend on the might of the high-speed dental drill to carry out crucial procedures such as creating space for fillings, crowns, and veneers. Packed with electric power, this mighty device can zoom up to 300,000 rotations per minute, allowing dentists to conduct treatments with immense precision.

The motor serves as the driving force of the high-speed dental drill, connected to the drill bit by a flexible shaft. An essential tool for dental professionals, this drill bit is an integral part made up of both a metal shank and a cutting head. The latter is crafted with tungsten carbide, an extremely durable metal alloy which is able to effectively penetrate tooth enamel. Together, these parts facilitate precise drill operations.

To guide a drill bit, a secure and adjustable chuck is required. It allows the bit to be held firmly while enabling precise depth control. The motor then helps set the pace, as going faster results in more effective and precise cutting.

Dentists have a powerful ally in the high-speed dental drill; its incredibly strong ability to cut through even the toughest materials, such as bone and enamel, enables dentists to carry out their work accurately and swiftly. And with its pinpoint accuracy, dentists can more safely navigate difficult operations without risk of harming surrounding tissue. Thanks to its formidable speed, dentists are able to finish their treatments quickly and efficiently.

Working with a drill requires great responsibility and care, especially considering the significant harm it can potentially inflict. Firstly, sturdy eye-protection is essential; as the drill creates tremendous heat and an amalgamation of disordered material which could cause grave damage to the eyes. Furthermore, the high elements of intensity ought to be avoided around those with a pacemaker installed, as it might affect the functionality of the device. Finally, caution and vigilance should be exercised to keep any harm or injury from occurring due to mishandling.

Durings its vigorous spins of up to 300,000 RPM, the high-speed dental drill is an incomparable asset for dentists. Its rapid rotations offer speed and precision for a variety of cutting tasks. Nevertheless, this impressive tool must be handled with caution or else run the risk of inflicting grave harm. As long as utilized properly and responsibly, the high-speed dental drill can be a tremendous boon to dental practices.

Dentists rely on the high-speed dental drill to accurately remove decay, shape and restore teeth, and prepare them for filling – all at lightning-fast speeds of over 200,000rpm. Compare this to the average ceiling fan, which can only manage a meager 200rpm! Indeed, this mighty tool is a precise and powerful asset in a dentist’s arsenal, allowing them to quickly and confidently perform complex procedures.

With the assistance of a turbine-driven motor, the dental drill operates at tremendously rapid and adjustable speeds to facilitate the necessary procedure. The turbine engine finds its power source in compressed air, though occasionally electric energy is used. Connected to the drill bit is a bendable shaft; this connection affords the dentist full oversight over the direction and velocity of the drill.

To provide superior quality results, the drill bit can come in either diamond or carbide – the former being the more expensive option but with greater longevity. The latter may be more economical but its level of durability is not far behind. Both materials allow for a remarkably smooth finish and the utmost precision in detailing tooth shapes and contours.

After administering a local anesthetic to numb the area, the dentist will select an appropriate drill bit for the task and then firmly affix it to the spinning turbine motor. The process of employing a high-speed dental drill is remarkably straightforward. Doing so helps ensure a more comfortable experience for the patient.

With the dental drill bit securely attached, the dentist proceeds to modify the speed and path, taking into consideration the specific treatment. If decay removal is on the roster, then a high rate of power is engaged and drill movements take a circular form. As the dentist drives the drill bit through the affected area, decay is systematically eliminated until complete.

The drill bit will be carefully operated at a slower speed, moving in a pendulum-like pattern. This technique ensures that the dimensions of the cavity are aptly amended, allowing the filling substance to be perfectly placed and firmly secured.

With its phenomenal 208,000 rpm speed, the high-speed dental drill is an absolute must-have tool for precise and lightning-quick dental procedures. Its user-friendly design allows dentists to adjust both the speed and direction of the drill according to the task at hand. The carbide and diamond point drill bits allow for intricate shaping and contouring – no detail overlooked! All in all, the electric dentist drill is a highly potent weapon in the fight against tooth decay, enabling practitioners to perform a vast range of treatments with unprecedented accuracy.

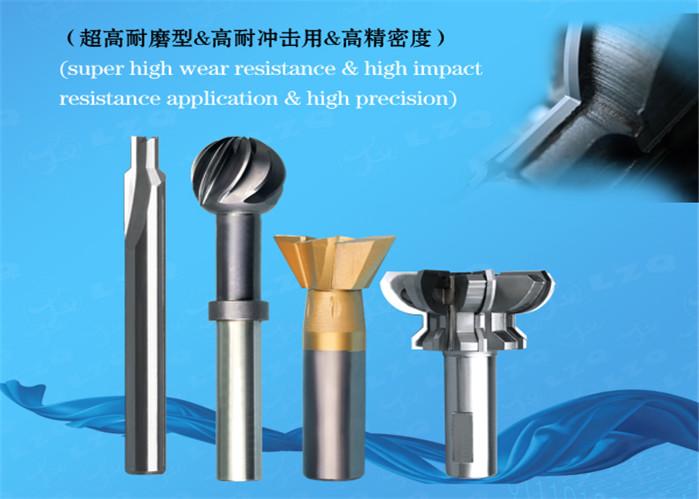

Related Product

Step Bur Milling Bur Grinder for Glass Cerami

Product Information Origin Tianjing, China Shank Diameter 1.8 (mm) Brand MSK Scope Of Application CEREC3 Grinding Equipment Material Stainless Steel/Carbide Main Sales Areas […]

Supply Roland DLC Zirconia Burs

Product Information Origin Tianjing, China Series Dental Bur Brand MSK Cutting Edge Form 2 Blade/3 Blade Ball Diameter (Mm) 0.6, 1, 2 Material Very Fine Grained Cemented Car […]

Diamond Coating Round Diamond Cutters

Product Information Origin Tianjing, China Series U Series Brand MSK Cutting Edge Form Helical Structure Ball Diameter (Mm) 3 Material Carbide Minimum Cutting Diameter At Th […]

HP Deburring Carbide Burs

Product Information Brand MSK Material Tungsten Steel Model Grinding Head Custom Processing Yes Feature: The dental grinding head is made of tungsten steel with stabl […]

Dental CAD/CAM Milling Burs

Product Information Origin Tianjing, China Material Stainless Steel Brand MSK Applicable Machine Tools A Variety Of Options Custom Processing Yes Whether To Coat No Is It a […]

Carbide Roland CAD/CAM Burs

Product Information Origin Tianjing, China Brand MSK Number Of Blades 4 Product Name Dental Special 4-Blade End Mill Model D Number Of Blades Z X N L d 4TD2060HB 2 4 […]

Diamond Bur Ball Round

Product Information Product Name Dental 4-Flute Ball End Mill Brand MSK Model D Number Of BladesZ X N L d 4BTD2060 2 4 6 6 50 3 4BTD2010 2 4 6 10 50 3 4BTD2016 2 4 6 […]

Post time: 2023-07-06