For the uninitiated, the price of carbide burs can be a cause for concern. But what exactly are they? In truth, they are simply small cutting tools crafted from a combination of two metals, tungsten carbide and cobalt, and are used in an array of projects that need grinding, shaping or finishing on metal, wood and even plastic components. Of course, the cost of these burs fluctuates based on their type, size and what their purpose is.

When making an investment in carbide bur tools, there are two primary elements that will affect the prices; their size and the cutting tip type. Typically, smaller burs come at a lower price point due to their versatile functionality – able to handle fine details, while larger burs offer more aggressive cuts. Furthermore, the cutting tip of your tool can also vary in cost – ranging from straight and tapered blades to ball-shaped tips; with each variation offering unique levels of performance and precision. Essentially, the more advanced cutting tip selected, the greater the expense.

When searching for the most affordable carbide burs, it pays to do research on the various purchasing options around. With several approaches to purchase burs, from online stores to traditional tool and equipment vendors, a price comparison will guarantee the highest savings. Saving money requires taking the time to explore all the possibilities – and, of course, making sure you get the best deal.

When examining the cost of carbide burs, quality is a significant factor; something to take into consideration. Low-cost options are likely constructed using lesser materials, and thus probably won’t be able to offer the same performance as their premium counterparts. In other words, you get what you pay for.

Aside from the bur itself, buyers must be mindful of the cost of companion items that accompany it, such as bits and grinding stones. While seemingly minor expenses, when considered collectively, the cost of these can add up rapidly and should therefore be figured into an individual’s carbide bur budget.

When searching for carbide burs, shoppers should be aware that prices can fluctuate greatly depending on an array of characteristics such as size, quality, and cutting tip. To secure the best purchase without financial strain, it is wise to compare prices from various suppliers. Furthermore, they should also consider the cost of associated accessories when budgeting. This way, buyers are guaranteed a bang-for-their-buck product without breaking the bank.

For those searching for economical carbide bur options, prices have skyrocketed – yet there remains a plethora of possibilities. This article explores the different varieties of carbide bur, the current cost levels, and how to purchase them at the best bargains.

With a variety of sizes and shapes, carbide burs supply cutting and shaping aptitudes for countless materials – including metal, wood, and plastic. Depending on the type of carbide used in fabrication, as well as the size and number of cutting edges, each style of carbide bur varies in price.

For anyone on a budget, uncoated carbide burs are the way to go. Ranging in size from 1/8” to 1”, they can be purchased for anywhere between $2 and $10 apiece. Unfortunately, their cutting edges are not as resilient as those of coated burs and require more frequent replacement.

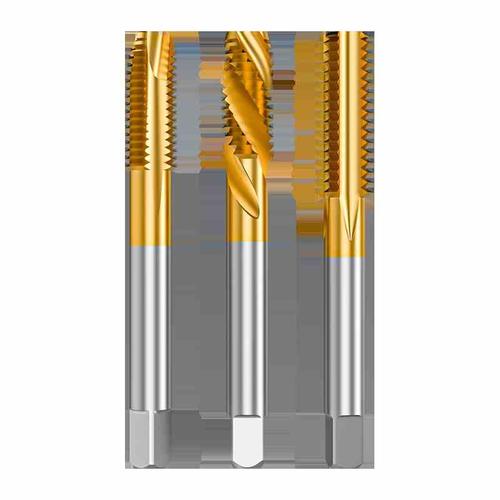

Although it costs more initially, investing in coated carbide burs is a worthwhile choice. These burs can last up to three times longer than the uncoated alternative, paying for themselves in longevity alone. Generally priced between seven and twenty dollars each, titanium nitride coating is commonplace; the hardy, wear-resistant layer safeguards the cutting edges, helping them stay honed for longer.

For those interested in tackling machining projects that require extra strength and durability, diamond-coated burs provide a powerful cutting solution. Officially dubbed carbide burs, these materials have been specially coated with abrasive diamond particles, capable of slicing through even the most recalcitrant surfaces. Prices for these speciality tools tend to range between $20 and $50.

When purchasing carbide burs, you must evaluate the quality of the material used. Cheaper, low-grade carbide can reduce their durability and efficiency, so it is paramount to examine the grade before buying them. Additionally, take into account the size and shape you are looking for as well as the number of cutting blades.

In order to acquire the best bargains on carbide burs, browsing a variety of retailers is essential. There are abundant opportunities online to discover discounts and promotions when it comes to carbide burs, thus investing time into comparing prices is advised. Additionally, requesting information about possible bulk savings when making a purchase can be beneficial as many tool suppliers offer such incentives.

All in all, the price of carbide burs has climbed in recent years, yet there remain numerous choices for those hunting for the most attractive costs on their carbide burs. The type of carbide at use, the size and number of cutting edges, and the quality of the burs are all considerations that ought to be assessed as you are looking to purchase. Moreover, it is essential to compare prices to guarantee you are obtaining the most competitive deal on your carbide burs.

Related Product

Carbide Roland CAD/CAM Burs

Product Information Origin Tianjing, China Brand MSK Number Of Blades 4 Product Name Dental Special 4-Blade End Mill Model D Number Of Blades Z X N L d 4TD2060HB 2 4 […]

Supply Roland DLC Zirconia Burs

Product Information Origin Tianjing, China Series Dental Bur Brand MSK Cutting Edge Form 2 Blade/3 Blade Ball Diameter (Mm) 0.6, 1, 2 Material Very Fine Grained Cemented Car […]

Step Bur Milling Bur Grinder for Glass Cerami

Product Information Origin Tianjing, China Shank Diameter 1.8 (mm) Brand MSK Scope Of Application CEREC3 Grinding Equipment Material Stainless Steel/Carbide Main Sales Areas […]

Diamond Coating Round Diamond Cutters

Product Information Origin Tianjing, China Series U Series Brand MSK Cutting Edge Form Helical Structure Ball Diameter (Mm) 3 Material Carbide Minimum Cutting Diameter At Th […]

HP Deburring Carbide Burs

Product Information Brand MSK Material Tungsten Steel Model Grinding Head Custom Processing Yes Feature: The dental grinding head is made of tungsten steel with stabl […]

Dental CAD/CAM Milling Burs

Product Information Origin Tianjing, China Material Stainless Steel Brand MSK Applicable Machine Tools A Variety Of Options Custom Processing Yes Whether To Coat No Is It a […]

Diamond Bur Ball Round

Product Information Product Name Dental 4-Flute Ball End Mill Brand MSK Model D Number Of BladesZ X N L d 4BTD2060 2 4 6 6 50 3 4BTD2010 2 4 6 10 50 3 4BTD2016 2 4 6 […]

Post time: 2023-07-17