An experienced craftsman’s toolbox is never complete without carbide burs. These cutting, grinding, and polishing tools can be used for a multitude of projects involved with metalworking, woodworking, and automotive industries. The variation of shapes, sizes, and grades available mean there is a carbide bur suitable to every task. In fact, nothing else comes close to being as versatile as the carbide bur.

A blend of tungsten carbide and cobalt form the basis of Carbide burs, rendering them far harder and longer-lasting than most. This composite construction equips them for cutting, grinding, and polishing a broad array of substances – metal, wood, plastic, and even stone! As for size and shape, there is great variability: from the mini cylindrical types to the sizable flat-tipped ones. The caliber of each bur and its particular shape dictate how effectively it can manipulate different materials while producing high levels of accuracy.

Sorting through the various types of carbide burs can be daunting, but understanding the purpose of each type is essential when selecting the one that is right for your project. Depending on the material being worked on, a softer or harder grade of bur may be more suitable. Soft materials like plastic or wood can be optimally ground by a milder bur, whereas one with higher grade hardness may be best able to tackle metal. Furthermore, knowledge of its size and shape are important to consider since they will significantly influence the precision and control you have over your results.

When it comes to buying carbide burs, quality is key. With a range of suppliers on the market, consumers need to make sure the company they buy from is reliable. Researching reviews and taking time to understand what kind of burs are most suitable for a given task can help ensure good value for money and peace of mind.

The metalworking, woodworking, and automotive fields depend upon the presence of carbide burs. These illustrious tools can be used in multiple scenarios- sanding, clarifying, drilling- and are able to provide astonishing levels of accuracy when the correct kinds of operations need to take place. Whenever searching for carbide burs, it is important to determine the appropriate material type for the task at hand, as well as the size and grade which will factor into how effectively they can perform. It is also necessary to source these items from a renowned provider so that one can feel certain that there is top-tier quality and precision being achieved. With the appropriate bur and supplier, any worker in these professions can rest assured that their necessary work is in reliable hands.

Unveiling a Workshop Must: Carbide Burs for Sale

To any workshop, carbide burs are a critical piece of equipment. Delivering an optimal result when machining and grinding materials like metal, wood, and plastic, they are highly regarded in automotive, aerospace, and industrial settings. Moreover, a vast range of applications can be accomplished with the versatile and dependable nature of these tools.

To create a tool that is incredibly sturdy and reliable, carbide burs are formed from a combination of tungsten carbide and cobalt. They boast sharp and precise cutting edges, enabling machining and shaping of even the most challenging materials with remarkable accuracy. With various sizes and shapes available, it is easy to find a carbide bur that fits any given task.

A straight carbide bur is a necessary staple for the everyday machinist. This tool features a flat cutting edge, making it suitable for a variety of materials and general grinding tasks. When more detail-oriented work requires extra finesse, a ball-shaped bur is an ideal option. With its rounded cutting edge, this tool provides the precision required to complete intricate functions.

An array of sizes and lengths are accessible when selecting carbide burs; the shank size will determine which machine is suitable to use it on, while the bur length reveals the cut depth. Before purchasing, make sure that the dimensions are appropriate for the intended application.

Shopping for carbide burs locally or online requires care. Customers seeking discounts on bulk orders or free-shipping should be diligent when choosing an online supplier. Before committing to a purchase, it is wise to analyse customer reviews to gauge the quality of the product.

When using a carbide bur, it is imperative to don protective paraphernalia like goggles and hearing protectors. These tools can become immensely hazardous if handled with neglect, as they produce plenty of heat and expel particles which one should be aware of. Moreover, it is essential to comply with the maker’s advice for utilization and maintenance.

Any carpenter, mechanic, or DIY enthusiast should have a set of carbide burs at their disposal. Their versatility makes them essential for a wide range of projects, and they are widely available in varying sizes and shapes. Before use, though, it’s essential to take all necessary safety precautions as outlined by the manufacturer and regularly inspect them to ensure longevity. With proper attention and care, these burrs can easily provide years of productive use.

Related Product

Supply Roland DLC Zirconia Burs

Product Information Origin Tianjing, China Series Dental Bur Brand MSK Cutting Edge Form 2 Blade/3 Blade Ball Diameter (Mm) 0.6, 1, 2 Material Very Fine Grained Cemented Car […]

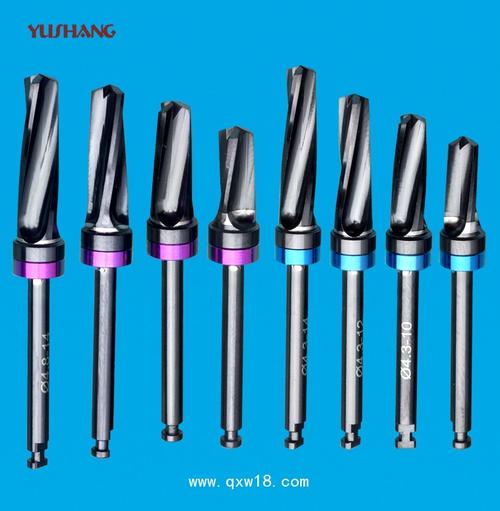

Step Bur Milling Bur Grinder for Glass Cerami

Product Information Origin Tianjing, China Shank Diameter 1.8 (mm) Brand MSK Scope Of Application CEREC3 Grinding Equipment Material Stainless Steel/Carbide Main Sales Areas […]

Diamond Coating Round Diamond Cutters

Product Information Origin Tianjing, China Series U Series Brand MSK Cutting Edge Form Helical Structure Ball Diameter (Mm) 3 Material Carbide Minimum Cutting Diameter At Th […]

Carbide Roland CAD/CAM Burs

Product Information Origin Tianjing, China Brand MSK Number Of Blades 4 Product Name Dental Special 4-Blade End Mill Model D Number Of Blades Z X N L d 4TD2060HB 2 4 […]

Dental CAD/CAM Milling Burs

Product Information Origin Tianjing, China Material Stainless Steel Brand MSK Applicable Machine Tools A Variety Of Options Custom Processing Yes Whether To Coat No Is It a […]

HP Deburring Carbide Burs

Product Information Brand MSK Material Tungsten Steel Model Grinding Head Custom Processing Yes Feature: The dental grinding head is made of tungsten steel with stabl […]

Diamond Bur Ball Round

Product Information Product Name Dental 4-Flute Ball End Mill Brand MSK Model D Number Of BladesZ X N L d 4BTD2060 2 4 6 6 50 3 4BTD2010 2 4 6 10 50 3 4BTD2016 2 4 6 […]

Post time: 2023-07-18