The Carbide Flame Burr is an essential tool when it comes to creating detailed and intricate pieces of artwork. For years now, artisans have used this sturdy and reliable tool to effectively carve a broad range of materials, including wood, plastic, metal, and stone. With utmost precision, accuracy and control, the Carnide Flame Burr can be used to produce stunningly intricate craftsmanship on any of these materials.

By utilizing a high-temperature flame, Carbide Flame Burrs are heated at the tip, causing the carbide within to expand and easily cut through whatever material it is being used on. The burr is guided through the material, carving out a smooth and precise finish. With a selection of various shapes and sizes, these burrs offer a large variety of cutting possibilities.

Utilizing a carbide flame burr demands extra caution. To avoid any negative effects, its sharpness and condition should be thoroughly checked before use. Moreover, making sure it is stored in a dry area is an absolute must in order to shun rust accumulation. Additionally, protective apparel should be worn when handling the device since its generated heat can literally cause serious burns.

For a myriad of tasks, Carbide Flame Burrs are the pinnacle choice. Engraving patterns and designs, formcutting inlays, smoothening surfaces – their capabilities are endless. No matter the level of intricacy, whether making contoured corners or complex 3D shapes, these burrs can do it all!

Those looking to delve into detailed work will be more than pleased with Carbide Flame Burrs. They’re an incredible deal for the price, as they’re highly accessible and make it simple to construct distinctive shapes and styles into projects. Add in the fact that these burrs present the opportunity to incorporate a one-of-a-kind flair to your designs, and they become the optimal option for even the most sophisticated craftsman.

If you’re looking for a tool to jumpstart your entre into fine detailing, Carbide Flame Burrs are the perfect choice! Not only are they simple and affordable, but these burrs are also capable of crafting formidably detailed designs and shapes. Besides this, you can rely on them to quickly carve out flat surfaces or construct delicate rounded corners and edges. Furthermore, 3D shaping opportunities open up a whole new realm of customizing potential.

A carbide flame bur is an incredibly tough, reliable tool used for cutting and shaping an array of different materials like metal, plastic and stone. This bur is customarily employed by businesses in the manufacturing and woodworking fields; however, it also carries its worth among more creative areas such as jewelry making, sculpture, and medical device production. It is composed of a mix of tungsten carbide particles and a bonding agent, causing it to possess remarkable strength that can be hurled against even the most resilient materials.

The unmistakable heat and precision of a carbide flame bur is a common sight in workshops and garages wherever metal needs to be shaped or cut. This tool excels at sawing through steel, brass, aluminum, and many other alloys thanks to its solid-state tungsten carbide blades. But their inner construction doesn’t stop there: these sharp lances also feature a self-sharpening design which ensures that as the old blades become blunt, sharp new edges are exposed to carry on the job.

Generally, burs are supported by a whirring electrical or air-powered motor that spins them at a rapid speed, enabling them to slice through materials effortlessly. The size and style of the cut are adjusted via a collet – which is a clamping device – which then grasps the bur securely and can be altered to whatever width required.

By employing the power of a carbide flame bur, intricate shapes and contours can be crafted onto a variety of materials. From straight-edged cuts to rounded contours, it grants users the capability to sculpt shapes unseen with conventional cutting tools, providing extended flexibility when engaging with metal surfaces.

Taking safety measures is paramount when making use of a carbide flame bur. Although it is capable of slicing through materials with briskness and effectiveness, any incorrect handling could lead to destruction. It is imperative to don protective eyewear and gloves to ward off debris and searing heat from the bur. Additionally, lubricating the bur with a cutting liquid helps lessen friction and prolong its useful life.

The carbide flame bur is a powerful cutting device made from a fusion of tungsten carbide particles and a bonding material; granting it an unparalleled degree of hardness and durability. It is renowned for its effectiveness in fields as varied as metalworking, woodworking, jewelry making, sculpture, and medical device production. When connected to an air or electric powered motor, the bur is capable of spinning at tremendous velocities; easily slicing through any material in its way. Appropriate safety measures must be taken when working with a carbide flame bur as the material stands capable of causing substantial harm if mishandled.

Related Product

HP Deburring Carbide Burs

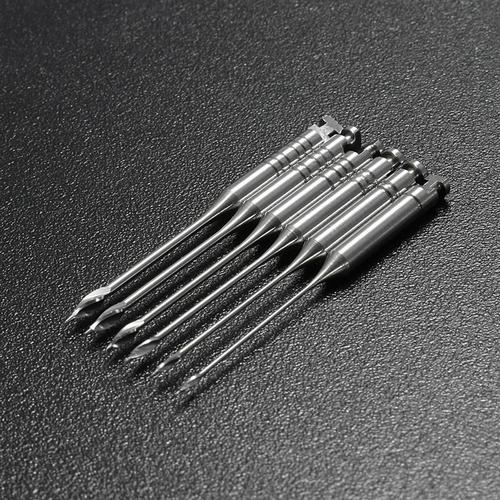

Product Information Brand MSK Material Tungsten Steel Model Grinding Head Custom Processing Yes Feature: The dental grinding head is made of tungsten steel with stabl […]

Diamond Bur Ball Round

Product Information Product Name Dental 4-Flute Ball End Mill Brand MSK Model D Number Of BladesZ X N L d 4BTD2060 2 4 6 6 50 3 4BTD2010 2 4 6 10 50 3 4BTD2016 2 4 6 […]

Dental CAD/CAM Milling Burs

Product Information Origin Tianjing, China Material Stainless Steel Brand MSK Applicable Machine Tools A Variety Of Options Custom Processing Yes Whether To Coat No Is It a […]

Diamond Coating Round Diamond Cutters

Product Information Origin Tianjing, China Series U Series Brand MSK Cutting Edge Form Helical Structure Ball Diameter (Mm) 3 Material Carbide Minimum Cutting Diameter At Th […]

Supply Roland DLC Zirconia Burs

Product Information Origin Tianjing, China Series Dental Bur Brand MSK Cutting Edge Form 2 Blade/3 Blade Ball Diameter (Mm) 0.6, 1, 2 Material Very Fine Grained Cemented Car […]

Carbide Roland CAD/CAM Burs

Product Information Origin Tianjing, China Brand MSK Number Of Blades 4 Product Name Dental Special 4-Blade End Mill Model D Number Of Blades Z X N L d 4TD2060HB 2 4 […]

Step Bur Milling Bur Grinder for Glass Cerami

Product Information Origin Tianjing, China Shank Diameter 1.8 (mm) Brand MSK Scope Of Application CEREC3 Grinding Equipment Material Stainless Steel/Carbide Main Sales Areas […]

Post time: 2023-07-15