Seeking a permanent solution for missing teeth? Dental implants could be the answer! These titanium posts are surgically placed into the jawbone, then connected to a prosthetic tooth. A successful dental implant can not only enhance your look, but also ensure smooth speaking and boost your oral wellbeing.

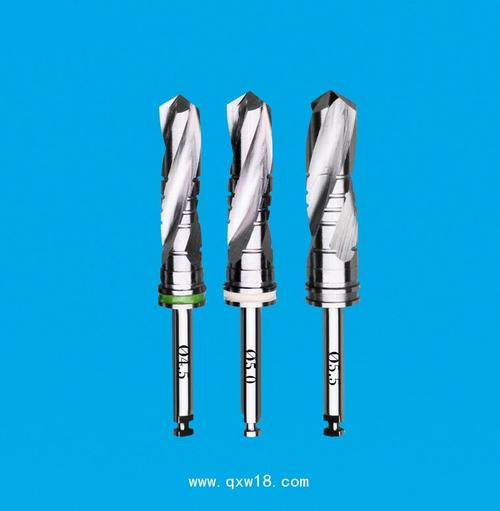

The use of a Computer-Aided Surgery Drill (CAS Drill) is an important aspect of the implant process. This technology, a combination of computer guidance and precision drill components, works to place the dental implants with maximum accuracy and minimal tissue trauma. As such, any potential for post-operative pain or swelling is significantly diminished.

Utilizing cutting-edge 3D imaging, the CAS drill works to construct a virtual clone of the patient’s jawbone in order to precisely chart the implant’s position. What’s more, numerous sensors are implemented to ensure that the process is accurate and dependable by monitoring the progress.

The CAS drill is famed for its immaculate accuracy, and it is frequently utilized in implant operations. Though the utilization of a CAS Drill fortifies the chances of an effective implant procedure, the healer must stay attentive to ascertain correct positioning of the implant for a successful end result.

After the implant is securely implanted, the dentists uses a CAS drill to delicately bore a cavity for the prosthetic tooth. The highly precise drill carves into the jawbone, giving the prosthetic enough grip that it remains secure and stable. With this intricate tool, a perfect fit is ensured – designed to keep in place for years to come.

The dental implant process relies heavily on the precision of a CAS drill to minimize tissue trauma. Although it is a reliable tool, its utilization does not guarantee the success of the placement. A talented surgeon must still pay close attention to the exact position of the implant for a successful procedure.

Modern dentistry has witnessed a remarkable improvement with the advent of dental implants. These implants offer an assured, efficient solution to treat lost teeth and reset oral aesthetics as well as functioning. More significantly, the process requires the utilization of the CAS drill, broadening the availability of dental remedies.

The Computer Aided Surgery (CAS) drill is a cutting-edge tool utilized in dental implant procedures. This precisely calibrated, computer-managed drill enables dental surgeons to place the implants with greater assurance and accuracy. As faults in implant placement can be detrimental to the success of a procedure, the CAS drill reduces the potential for human error and helps ensure positive outcomes. In essence, this leading-edge technology is an important asset when it comes to dental implant surgery.

For the CAS drill to do its job, three fundamental components are needed: a computer, a drill, and a handpiece. The computer is in charge of coordinating the drill operations and the handpiece movements. Utilizing the power of the rotary drill, a tiny hole is created in the jaw where the implant will be placed. The handpiece is responsible for managing the speed and direction of the drilling, while a LED light and magnifying glass are additional features to aid the dental personnel in seeing clearly.

Before the installation of the implant, the dentist will gather x-ray and 3D imaging data from the patient’s mouth to locate the precise spot and measure its size. Utilizing a computer, they will program a CAS drill to accurately create the necessary hole for the implant. With a high level of precision, the CAS guarantees that both its depth and placement are ideal, thus securing there is no harm done to nearby tissues.

After the dental surgeon drills into the jawbone, the implant is positioned inside and secured using a protective covering. To ensure the implant firmly Rooted, it needs to heal for some time before a connecting abutment and crown are affixed.

A dental implant procedure is not complete without utilizing the equipment of a CAS drill, which is both an advancement and necessity in the field of modern dentistry. This tool has created innovations, allowing for accurate and secure placements that wouldn’t have been possible previously. Above all else, the CAS drill is incredibly precise and reliable, making it a dependable asset for many dental practitioners.

Related Product

Diamond Bur Ball Round

Product Information Product Name Dental 4-Flute Ball End Mill Brand MSK Model D Number Of BladesZ X N L d 4BTD2060 2 4 6 6 50 3 4BTD2010 2 4 6 10 50 3 4BTD2016 2 4 6 […]

Step Bur Milling Bur Grinder for Glass Cerami

Product Information Origin Tianjing, China Shank Diameter 1.8 (mm) Brand MSK Scope Of Application CEREC3 Grinding Equipment Material Stainless Steel/Carbide Main Sales Areas […]

Carbide Roland CAD/CAM Burs

Product Information Origin Tianjing, China Brand MSK Number Of Blades 4 Product Name Dental Special 4-Blade End Mill Model D Number Of Blades Z X N L d 4TD2060HB 2 4 […]

Dental CAD/CAM Milling Burs

Product Information Origin Tianjing, China Material Stainless Steel Brand MSK Applicable Machine Tools A Variety Of Options Custom Processing Yes Whether To Coat No Is It a […]

Diamond Coating Round Diamond Cutters

Product Information Origin Tianjing, China Series U Series Brand MSK Cutting Edge Form Helical Structure Ball Diameter (Mm) 3 Material Carbide Minimum Cutting Diameter At Th […]

Supply Roland DLC Zirconia Burs

Product Information Origin Tianjing, China Series Dental Bur Brand MSK Cutting Edge Form 2 Blade/3 Blade Ball Diameter (Mm) 0.6, 1, 2 Material Very Fine Grained Cemented Car […]

HP Deburring Carbide Burs

Product Information Brand MSK Material Tungsten Steel Model Grinding Head Custom Processing Yes Feature: The dental grinding head is made of tungsten steel with stabl […]

Post time: 2023-07-26