Tiny cutting implements, known as dental burs, have been a fundamental part of the dentist’s toolkit for decades. By employing them, dentists are able to modify tooth surfaces, remove existing prostheses, attach composite adhesives or amalgam fillings, and craft preparation areas for crowns and bridges. Being extremely hardy and precise, dental burs can readily penetrate through potent ceramic and metal surfaces.

A variety of bur shapes and sizes can be found crafted from materials like diamond, tungsten carbide, and steel. The shank of each bur is connected to the dental handpiece while the cutting end forms the head and tip. This end may be round, or feature a flute constructed to carve into the tooth.

There is a wide range of dental burs, each distinguished by its form, magnitude, and cutting flute. The most prevalent shapes are spherical, conical, pear-shaped, and tapering. The size of the bur is dictated by the diameter of its shank and its cutting flute span.

The primary materials for dental burs, or cutting instruments, include diamond, tungsten carbide, and steel. Diamond burs are the most costly option, yet they boast impressive durability and cut strength. Tungsten carbide burs come at a lower price point but have a decreased resistance to wearing away as well as a propensity for breakage. Steel burs provide the least expense but also the briefest strength and durability.

Prepping enamel for bonding and eradicating old dental restorations require a specialized tool such as diamond burs. Reshaping and contouring can also be attained through diamond burs, though their effectiveness is limited to removing minor amounts of tooth enamel. For more substantial abrasion, tungsten carbide burs are required for removing greater amounts of enamel and for cutting through challenging materials like ceramic or metal restorations. Meanwhile, softer materials like amalgam and composites are easier to manipulate with steel burs.

The speed and pressure when using dental burs needs to be precise, as speeds above 20,000 RPM pose a colossal risk of fracture. In order to decrease the likelihood of heat-induced fractures occurring, dental burs must be used in combination with a water-cooling system.

To guarantee accuracy and safeguard patients, dental burs which are specially fashioned for the process ought to be the only instruments which dentists employ. These burs should possess the correct size, construction, and sharpness for the task at hand, as well as be thoroughly sterilized between patient visits.

To cap it all off, dental burs play a major role in the dental profession, where they are deployed to give teeth the required shape and proportion for numerous treatments. From assorted proportions and materials to velocities and pressures, these crucial instruments need to be used with great care.

In dentistry, dental burs are tools that allow dental practitioners to modify the shape, remove material, and polish the edges of teeth. These pieces of equipment come in assorted materials, including steel, diamond, and carbide, and vary in size and shape. Dentists routinely rely on them to analyze decay, form cavities for crowns, prepare teeth for filling, and refine the edges of restorations.

To facilitate cutting materials such as metal, ceramic, enamel, and dentin, dental burs come in a range of designs. Round burs produce a smooth, semicircular cut, while tapered varieties can be used to create a tapered, step-like shape when they remove material. Whatever material is being cut, these dental tools are designed to ensure the precision needed for a successful outcome.

Burs come in an assortment of sizes and forms. High-speed burs are intended for a rapid and proficient cutting process, whereas, slow-speed burs are better suited for precise tasks. Micro-motor burs represent the smallest of the bunch and are perfect for intricate detailing.

When it comes to your dental bur, attention to detail (and safety!) is key. It is critical to be mindful of the correct technique when utilizing a bur. Wear safety glasses and a face mask to shield yourself from the spinning bur, and ensure that you are clasping the bur firmly in your hand. As you start to work on your project, use circular motion and apply pressure steadily and evenly, being careful to neither press too hard nor twist the bur as this can cause it to splinter.

Inspecting the bur is a crucial step prior to use; this ensures that it is free of any damage that could potentially hinder its performance. Additionally, confirm that the bur’s cutting edge doesn’t have any stray debris, as this could cause it to malfunction.

Necessary for performing a multitude of dental operations, dental burs are instruments essential to forming, sculpting, and trimming teeth to craft the perfect smile. This careful and precise tool provides dentists with a secure and faster option to get the job done.

Related Product

Diamond Bur Ball Round

Product Information Product Name Dental 4-Flute Ball End Mill Brand MSK Model D Number Of BladesZ X N L d 4BTD2060 2 4 6 6 50 3 4BTD2010 2 4 6 10 50 3 4BTD2016 2 4 6 […]

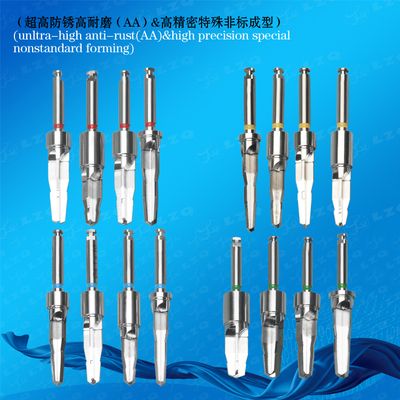

Dental CAD/CAM Milling Burs

Product Information Origin Tianjing, China Material Stainless Steel Brand MSK Applicable Machine Tools A Variety Of Options Custom Processing Yes Whether To Coat No Is It a […]

Diamond Coating Round Diamond Cutters

Product Information Origin Tianjing, China Series U Series Brand MSK Cutting Edge Form Helical Structure Ball Diameter (Mm) 3 Material Carbide Minimum Cutting Diameter At Th […]

Step Bur Milling Bur Grinder for Glass Cerami

Product Information Origin Tianjing, China Shank Diameter 1.8 (mm) Brand MSK Scope Of Application CEREC3 Grinding Equipment Material Stainless Steel/Carbide Main Sales Areas […]

Carbide Roland CAD/CAM Burs

Product Information Origin Tianjing, China Brand MSK Number Of Blades 4 Product Name Dental Special 4-Blade End Mill Model D Number Of Blades Z X N L d 4TD2060HB 2 4 […]

Supply Roland DLC Zirconia Burs

Product Information Origin Tianjing, China Series Dental Bur Brand MSK Cutting Edge Form 2 Blade/3 Blade Ball Diameter (Mm) 0.6, 1, 2 Material Very Fine Grained Cemented Car […]

HP Deburring Carbide Burs

Product Information Brand MSK Material Tungsten Steel Model Grinding Head Custom Processing Yes Feature: The dental grinding head is made of tungsten steel with stabl […]

Post time: 2023-07-08