Tungsten carbide rotary cutting tools, commonly referred to as dental burs, are essential for preparing dental restorations and are frequently utilized in both dental offices and laboratories. These small, round tools can be employed to precisely cut zirconia material, as well as harder surfaces including metal, porcelain, and acrylic. Additionally, softer materials such as wax and rubber can also be trimmed using a dental bur.

Zirconia has become an ideal material for dental work due to its remarkable strength and lasting durability. From crowns to bridges and beyond, this ceramic material is renowned for its sturdy quality and the attractive finish it produces. In addition, those with metal allergies are often drawn to zirconia for substitution, as it does not contain substances like nickel that may cause adverse reactions.

If you are embarking on working with zirconia, make sure to select the correct type of bur for your cutting task. Burrs that build for cutting zirconia have a finer-edged scythe than those that are utilized to cut other materials like porcelain, enabling a more efficient and precise cut. If you opt for the wrong bur, you may break or chip the material and unfortunately have to start from scratch. Therefore, using the appropriate bur for cutting zirconia is of paramount importance.

When selecting a bur for cutting zirconia, one should consider various important factors. The size and shape of the bur must match the size and shape of the zirconia restoration that is being cut – think a small, rounded bur for similarly small, rounded zirconia restorations, or a larger, flat bur for something larger and flatter. Additionally, the type of cutting edge must be chosen depending on the material that is being cut; different materials require different cutting edges. Finally, due to zirconia being a hard material, a bur running at a high speed should be employed.

Taking your time and being precise is the key to cutting zirconia using a dental bur. To be most successful, you’ll want to hold the bur at a perfect 90-degree angle against the surface of the zirocnai as you guide it steadily. It is imperative to utilize only the lightest of pressures; too much can lead to chipping or split pieces of material. To keep your bur from becoming overheated while cutting, that too can cause damage, don’t forget to cool it off in water in between passes.

Ultimately, the use of dental burs is a vitally important part of any activity where zirconia needs to be cut in a dental setting. Taking the correct type and size of bur, along with the appropriate technique, is essential for the cutting process to be done perfectly and without harming the zirconia. When these suggestions are taken into account, it is possible to make sure that the zirconia is cut accurately and in a secure manner for a successful dental restoration.

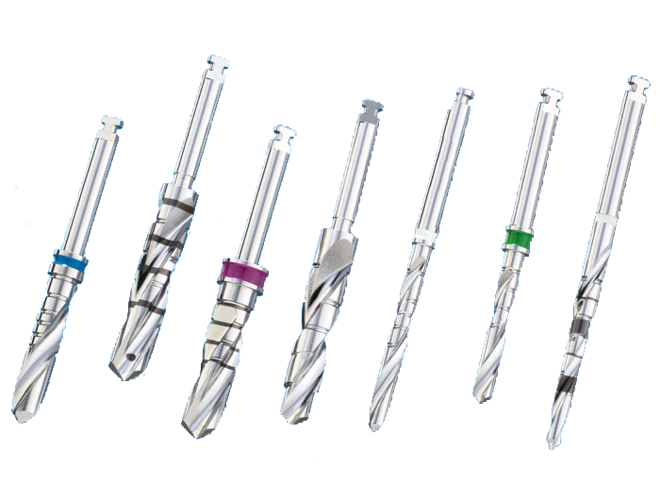

From cavity preparation to crown fabrication, dental burs are a prominent instrument in the dental trade for shaping and sculpting hard elements such as zirconia. There is an assortment of sizes and shapes of dental burs, but this area of the dental field recently underwent advancement with new burs engineered to raise the bar in cutting zirconia with greater efficiency and accuracy. This upgrade is intended to help dentists attain stellar results within a faster timeframe.

Diamond-coated burs are the dental tool of selection for cutting zirconia, as their diamond coating allows them to glide through the tough material with effortless ease, while preserving its strength and intact structure. These burs come in an assortment of shapes and sizes, providing users with a wide array of cutting options at their disposal, and are capable of creating smooth, neat incisions.

Designed with a coat of tungsten carbide particles, carbide-coated burs can afford a more aggressive cut than diamond-coated burs when used for cutting zirconia. Nonetheless, this tooltype should be employed with care as its abrasive properties can overly etch the material and incur damage. Available in various shapes and sizes, the carbide-coated bur presents an opportunity to customize the cutting process to whatever job requires.

To delicately cut zirconia, ceramic burs, with their ceramic coating, prove to be the ideal tool. Though more costly than its diamond-coated and carbide-coated bur counterparts, ceramic burs are well worth the investment given their exceptional slicing capability and capacity to protect the consistency of the zirconia material.

To achieve a smooth, clean cut with minimal damage to zirconia, a dental bur must be manipulated with the proper technique. This includes holding the bur at a 45-degree angle and gliding over the zirconia in a back and forth motion in a controlled manner. Additionally, the correct speed and pressure are essential for success- too much pressure can cause incompatible chipping or cracking of the material, while too little pressure can cause an early bur burn-out and a compromised finish.

To sum it all up, dental burs are an essential instrument in the dental trade, used to shape and fashion strong substances like Zirconia. Three particular kinds of burs that are used for this purpose are diamond-coated, carbide-coated and ceramic. It is critical to use an appropriate method, as well as an accurate speed and force when cutting through Zirconia with a dental bur. Doing this will allow dentists to complete their work efficiently while yielding the finest quality results.

Related Product

Carbide Roland CAD/CAM Burs

Product Information Origin Tianjing, China Brand MSK Number Of Blades 4 Product Name Dental Special 4-Blade End Mill Model D Number Of Blades Z X N L d 4TD2060HB 2 4 […]

Supply Roland DLC Zirconia Burs

Product Information Origin Tianjing, China Series Dental Bur Brand MSK Cutting Edge Form 2 Blade/3 Blade Ball Diameter (Mm) 0.6, 1, 2 Material Very Fine Grained Cemented Car […]

Diamond Bur Ball Round

Product Information Product Name Dental 4-Flute Ball End Mill Brand MSK Model D Number Of BladesZ X N L d 4BTD2060 2 4 6 6 50 3 4BTD2010 2 4 6 10 50 3 4BTD2016 2 4 6 […]

Dental CAD/CAM Milling Burs

Product Information Origin Tianjing, China Material Stainless Steel Brand MSK Applicable Machine Tools A Variety Of Options Custom Processing Yes Whether To Coat No Is It a […]

Step Bur Milling Bur Grinder for Glass Cerami

Product Information Origin Tianjing, China Shank Diameter 1.8 (mm) Brand MSK Scope Of Application CEREC3 Grinding Equipment Material Stainless Steel/Carbide Main Sales Areas […]

Diamond Coating Round Diamond Cutters

Product Information Origin Tianjing, China Series U Series Brand MSK Cutting Edge Form Helical Structure Ball Diameter (Mm) 3 Material Carbide Minimum Cutting Diameter At Th […]

HP Deburring Carbide Burs

Product Information Brand MSK Material Tungsten Steel Model Grinding Head Custom Processing Yes Feature: The dental grinding head is made of tungsten steel with stabl […]

Post time: 2023-07-10