Necessary for dental practitioners, the dental drill is a device essential to maintaining the health of patients’ pearly whites. This inventive Machinery carves cavities and cuts material from the teeth to construct fillings, crowns and other dentistry techniques. Additionally, with the assistance of this drill, dentists can cleanse and bring out the shine of tooth enamel.

After being utilized, a dental drill is polished with a particular finish to guard the bit and enhance its durability. This coat of polish also reduces the amount of debris which is produced during its operation.

Different types of dental drill-polishes are available to choose from. The most popular option is made with diamond dust, creating a glossy, glass-like surface on the drill bit. Having this polished finish helps minimize the force needed during drilling since it significantly reduces friction.

Tungsten Carbide polish is a special kind of crystalized abrasive developed for use on dental drill bits to create a reflective, glossy finish while reducing heat creation during the drilling process. Using these particles promotes smooth yet efficient action as it shaves away surface material.

To achieve a slick, glass-like texture on the drill bit, ceramic polish is often used. This polish consists of small ceramic particles that help to minimize heat production during the boring procedure. Applying this kind of polish helps create a fine and glossy finish.

If one is to employ a dental drill polish, then it is essential that they follow the maker’s guidelines when implementing it. It is similarly critical for individuals to utilize a compatible drill bit for the chosen polish.

Polish application on a drill bit requires a subtle touch, as excessive pressure can make the polish too thick, impeding its functionality. Subsequently, make certain that the bit is totally dry beforehand.

Before utilizing your drill bit, it is essential to give the polish enough time to settle in thoroughly. This will ensure that the coverage was uniform and your apparatus is guarded accordingly.

A well-oiled machine is essential in any dentist’s workspace. Polishing the dental drill bit with the appropriate tool helps prolong the lifespan of the tool as well as minimising debris creation during the drilling activity. By adhering to the guidance provided by manufacturers, dental professionals can make sure they polish their drill bits precisely and safeguard them too.

When it comes to providing quality dental care, dental drills are indispensable instruments. Crowns, fillings, and root canals are just a few of the many procedures which rely upon the precision of a dental drill. To ensure the highest calibre of outcomes, these tools must be regularly maintained and polished. In doing so, modern dentistry can continue to provide positive results for its patients.

Maintaining peak performance with a dental drill is a piece of cake–just a few simple steps and it is ready to go. Polishing the drill bit consists of scraping off any material residue that has been left on the bit, may it be because of the drilling itself or contamination from bacteria, saliva, or some other items. Failure to do so could mean reduced efficiency and a higher likelihood of infection. By taking a polishing wheel to the drill bit, one can make sure that the cutting edges are clean and pointed, ridding the bit of anything that might cause difficulty.

In order to get the job done just right, the polishing procedure is necessary. Start by scouring away any dirt or residue from the drill bit with a bristle brush or cleaning solution. When spotlessly clean, insert the drill bit into a spinning wheel and move it in circles at a slow speed. After several minutes, inspect the bit for any lingering remnants and make sure to give it another go until no further impurities remain.

To achieve a smooth finish, the drill bit must first be scrubbed free of all debris before being treated with a polishing compound. This substance comes in various forms, including pastes, creams, liquids, and sprays. Depending on which kind you use, you may need to employ the brush or the mister. Whatever the agent, you must move the bit back and forth in a rotating motion until it’s glossy and pristine.

Ultimately, a critical step in the drilling process is to examine the drill bit in detail. If the cutting edges or the bit itself shows sign of wear, tear, or even cracking, it is advisable to discard it and use a new one instead.

Dental drills require regular polishing and inspection in order to guarantee top performance and patient safety. A precise polish will eliminate any material accumulation from the drill bit and guarantee it is up to its utmost standards. This way, professionals can be certain the drill will produce the most favorable results while simultaneously meeting the highest safety standards for patients. By frequently inspecting and maintaining their instruments, dental teams can guarantee both excellent results and safe care.

Related Product

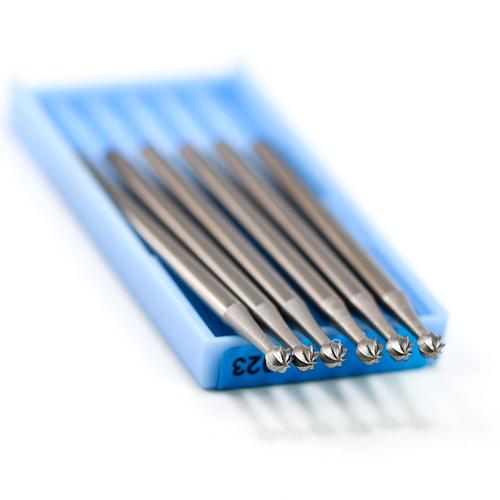

Diamond Bur Ball Round

Product Information Product Name Dental 4-Flute Ball End Mill Brand MSK Model D Number Of BladesZ X N L d 4BTD2060 2 4 6 6 50 3 4BTD2010 2 4 6 10 50 3 4BTD2016 2 4 6 […]

HP Deburring Carbide Burs

Product Information Brand MSK Material Tungsten Steel Model Grinding Head Custom Processing Yes Feature: The dental grinding head is made of tungsten steel with stabl […]

Dental CAD/CAM Milling Burs

Product Information Origin Tianjing, China Material Stainless Steel Brand MSK Applicable Machine Tools A Variety Of Options Custom Processing Yes Whether To Coat No Is It a […]

Supply Roland DLC Zirconia Burs

Product Information Origin Tianjing, China Series Dental Bur Brand MSK Cutting Edge Form 2 Blade/3 Blade Ball Diameter (Mm) 0.6, 1, 2 Material Very Fine Grained Cemented Car […]

Carbide Roland CAD/CAM Burs

Product Information Origin Tianjing, China Brand MSK Number Of Blades 4 Product Name Dental Special 4-Blade End Mill Model D Number Of Blades Z X N L d 4TD2060HB 2 4 […]

Step Bur Milling Bur Grinder for Glass Cerami

Product Information Origin Tianjing, China Shank Diameter 1.8 (mm) Brand MSK Scope Of Application CEREC3 Grinding Equipment Material Stainless Steel/Carbide Main Sales Areas […]

Diamond Coating Round Diamond Cutters

Product Information Origin Tianjing, China Series U Series Brand MSK Cutting Edge Form Helical Structure Ball Diameter (Mm) 3 Material Carbide Minimum Cutting Diameter At Th […]

Post time: 2023-08-01