When it comes to improved tooth aesthetic and functionality, dental implants are a tried-and-true method. Inserting the implant accurately to fill gaps or replace missing teeth is imperative. To ensure this precision, sophisticated instruments and tools are required. Maintaining these pieces in peak condition is the key to achieving successful results. That’s why dental implant drill sharpening is an essential part of any experienced practise, preserving quality and guaranteeing a perfect end result.

Titanium posts, known as dental implants, are surgically implanted into the jawbone. Here, they start to bond with the bone and become a steady anchor for a crown or bridge. The visible, gum-level part of the implant connecting to the tooth is called an abutment and serves as a link between it and the crown or bridge, allowing for a restored, beautiful smile.

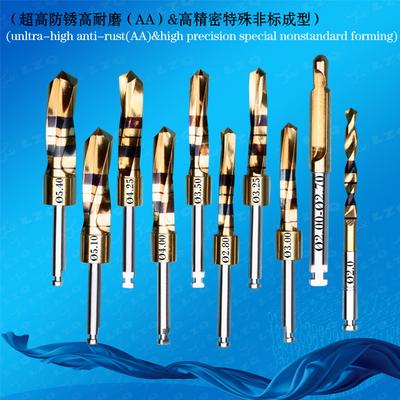

To make sure the implant is positioned in the best place possible, drilling is necessary to craft a hole into the jawbone and to fashion the bones surrounding it. The state of these drills needs to be optimal; thus, drill sharpening is an essential endeavor that cannot be neglected.

To ensure that it cuts through bone accurately and efficently, it’s necessary to hone the edges of a drill bit. This is known as sharpening – attentively and carefully abrading the blade to bring back its cutting power. If done incorrectly, though, it is possible to sharpen the drill too drastically and overdo it, posibly leading to damage occurring to the implant or tissues in its vicinity.

With dental implant placement, a drill bit requires special sharpening. This is done through a diamond bur, a handpiece with diamond particles capable of polishing the bit’s cutting edge. The bit is inserted into the bur, then rotated until the particles abrade and refine its surface, which restores the bit’s cutting capabilities and helps it pierce through the bone with precision.

Precision and care are essential when honing a bur for dental implant placement. To guarantee the most satisfactory outcome, the bur should be the same size as the drill bit and utilized properly. Furthermore, regular replacing of the bur is necessary; with its diamond particles experiencing attrition as time marches on, it will eventually become useless.

When it comes to dental implants, a sharp drill is essential for optimal results – but, the sharpening process takes skill and precision. Too much sharpening could lead to a drill that is too pointed, which may harm the implant or tissue surrounding it. For this reason, professional attention is crucially needed in order to inspect and properly sharpen the drill. Regular upkeep of the drill will ensure that patients receive excellent results each time.

Maintaining the quality of dental implant procedures relies heavily on the sharpness of dental implant drill bits, as this will impact the precision and endurance of the implant. To properly take care of the tool, it can be sharpened either by hand or with an automated system. No matter which approach is used, it is essential to ensure that the drill bit stays in top condition.

To get a dental implant drill bit running like new again, the initial step is to address any imperfections at its cutting edge. This can be done with the help of a diamond-tipped sharpening stone for a precise and reliable touch-up. Alternatively, a rotary sharpening tool will do the trick. Confirm that the sharpening stone you chose is the exact size and shape according to the drill bit being sharpened, as incorrectly doing so might worsen the drill bit or yield suboptimal results.

Having cleared away the blemishes and defects, it is now time to hone the cutting edge of the bit. This process can be achieved utilizing a rotating powertool, like a Dremel or Foredom, or with a manual sharpening tool. When using a rotary tool, it is vital to confirm that the rate has been properly set for the bit being sharpened. Spinning too fast may result in excessive heat that could harm the cutting edge of the bit.

To best prolong the life of the bit, it is essential to lubricate during use. Machine oil is a popular option as it effectively reduces friction and wear without damaging the bit. With a sharp cutting edge in place, simply apply a light coating of oil to both the drill and bit for optimal performance.

To guarantee efficiency in future dental implant procedures, inspect the bit for any signs of tear and damage. If any such indicators are present, immediately swap the bit with a brand-new one. However, if the bit appears to be acceptable, it can remain in service for on-going operations. Nevertheless, don’t forget to vigilantly monitor its condition; ensuring the bit stays viable is of utmost importance.

To achieve excellence in dental implant procedures, regular sharpening of the drill bit is essential. Ensuring that the bit is suitably grinded and oiled ensures an effective implant and a longer-than-usual lifespan. With due care, a dental drill bit can serve faithfully and precisely for many a year.

Related Product

Supply Roland DLC Zirconia Burs

Product Information Origin Tianjing, China Series Dental Bur Brand MSK Cutting Edge Form 2 Blade/3 Blade Ball Diameter (Mm) 0.6, 1, 2 Material Very Fine Grained Cemented Car […]

HP Deburring Carbide Burs

Product Information Brand MSK Material Tungsten Steel Model Grinding Head Custom Processing Yes Feature: The dental grinding head is made of tungsten steel with stabl […]

Step Bur Milling Bur Grinder for Glass Cerami

Product Information Origin Tianjing, China Shank Diameter 1.8 (mm) Brand MSK Scope Of Application CEREC3 Grinding Equipment Material Stainless Steel/Carbide Main Sales Areas […]

Diamond Bur Ball Round

Product Information Product Name Dental 4-Flute Ball End Mill Brand MSK Model D Number Of BladesZ X N L d 4BTD2060 2 4 6 6 50 3 4BTD2010 2 4 6 10 50 3 4BTD2016 2 4 6 […]

Carbide Roland CAD/CAM Burs

Product Information Origin Tianjing, China Brand MSK Number Of Blades 4 Product Name Dental Special 4-Blade End Mill Model D Number Of Blades Z X N L d 4TD2060HB 2 4 […]

Dental CAD/CAM Milling Burs

Product Information Origin Tianjing, China Material Stainless Steel Brand MSK Applicable Machine Tools A Variety Of Options Custom Processing Yes Whether To Coat No Is It a […]

Diamond Coating Round Diamond Cutters

Product Information Origin Tianjing, China Series U Series Brand MSK Cutting Edge Form Helical Structure Ball Diameter (Mm) 3 Material Carbide Minimum Cutting Diameter At Th […]

Post time: 2023-07-06