An indispensable tool in the dental practitioner’s kit, dental burs are designed to perform comprehensive tasks including cutting, sculpting, and buffing teeth. Offered in a plethora of sizes and shapes, these burs are ideally suited to carrying out a varried range of dental treatments.

With the purpose of cutting, sculpting and finishing teeth, a dental bur is a rotund apparatus fitted with a sharp edge. Crafted from materials such as steel, tungsten and carbide, these burs can be either single-ended or double-ended. To provide dexterity and accuracy in working with tooth enamel, the cutting edge of many of these burs is curved or serrated.

Utilizing Dental Lab Burs – A Dentist’s Tool

• In order to lay the groundwork for a filling, decayed or damaged enamel must be removed from the tooth.

Mold the enamel, crafting a crown, bridge, or any other prosthetic you desire.

After a dental treatment such as a filling or crown fitting, it is important to smoothen the surface of a tooth for a shiny overall shine.

• Carve out a hollow space from a tooth.

Orthodontic treatments require the deletion of any surplus enamel.

Prepare a opening for root canal therapy in order to gain access to the innermost parts of a patient’s tooth.

Create an even background for the integration of veneers or inlays.

When it comes to dental lab burs, there are a variety of shapes and sizes to choose from. At the top of the pricing scale are diamond burs, which are commonly used to carve and fashion enamel. Carbide burs, being on the cheaper side, are usually deployed for grinding and polishing teeth. The least costly type are steel burs, normally put to use for the cutting and sculpting of enamel.

The dentist must be precise when selecting the required bur. It must fit the size and configuration of the area to be treated. In order to ensure the optimal outcome, the material used in the manufacture of the bur should also be taken into consideration. Diamond burs, for instance, can efficiently deal with hard enamel surfaces, whereas steel is better suited to softer materials, such as composite fillings.

To protect the patient and the dental lab bur, it’s important for the dentist to be mindful of their speed. A slow pace of use is essential, and the tip of the bur should be monitored to avoid becoming overheated. Additionally, it is critical to maintain cleanliness and sterility in order to avoid the transmission of any infection.

Dentists and dental technicians rely on dental lab burs to delicately cut, shape, and refine teeth with pinpoint accuracy. The correct bur must be selected for each job, and then taken utmost care of both the patient and the bur must be taken by the dental professionals in order to ensure their safety.

For any dental practitioner, lab burs are an indispensable instrument. In the clinic, they are used to adjust and refurbish teeth enduring from damage or to ready them for reconditioning. But in the lab, these burs become more intricate, diligently carving and buffing crowns, bridges, and other dental prosthetic works.

Several shapes, sizes, and materials compose dental burs. Many opt for tungsten carbide, the most enduring and reliable option. Diamonds provide a sumptuous finish at the highest price point. High-speed steel burs represent the cost-efficient choice, though they may break sooner than others.

Crafting your desired look demands the right tools and materials, especially when it comes to dentistry. When deciding on a dental bur for your next project, take into account the type of substance you’re working with. Nothing is worse than putting in all that time and effort only to discover that your chosen bur isn’t suitable for that item. For example, if you’re dealing with porcelain, opt for a tungsten carbide bur as it is better suited for shaping and shining this material. Conversely, if you’re taking care of metal, such as gold, diamond burs are your best bet.

The size of the bur is of great significance in addition to opting for the correct variety. A selection of sizes exist, from those fine enough for detailed craftsmanship to those more general that handle much coarser work. Of course, this is not the only factor as multiple burs have been fashioned to tackle particular substances, like diamond burs to be used on porcelain and high-speed steel burs intended for metals.

Handling a bur demands extra care; this powerful yet precise tool has the potential to cause harm if it is not treated with proper respect. Be sure to equip yourself with the necessary protective gear, including goggles, and never leave your bur sitting freely: return it to its protective sleeve after each use to stave off potential injury.

Keeping your burs in top condition is essential, and it begins with regular cleaning and sharpening. Utilize a soft cloth with a mild detergent to get the job done right. To sharpen, you can use either an abrasive stone or a tool designed from the ground up to sharpen burs. Taking care of your burs on this level will give them a long lifespan.

Essential for any dental professional, the wide range of dental lab burs come in various sizes, shapes, and materials. Carefully selecting the right one for the job not only ensures efficient results but also eliminates the chance of any accidents. Furthermore, with regular cleaning and sharpening, a dental bur can stand the test of time.

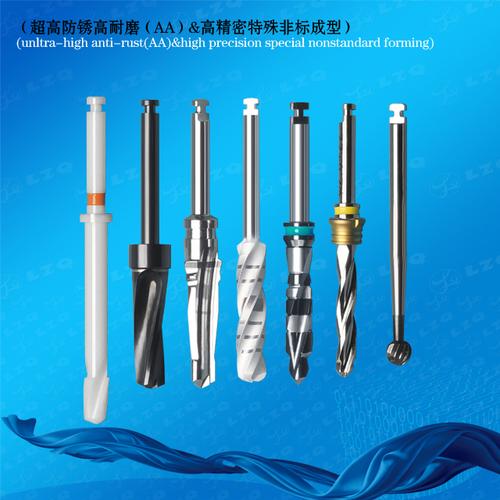

Related Product

Step Bur Milling Bur Grinder for Glass Cerami

Product Information Origin Tianjing, China Shank Diameter 1.8 (mm) Brand MSK Scope Of Application CEREC3 Grinding Equipment Material Stainless Steel/Carbide Main Sales Areas […]

Diamond Coating Round Diamond Cutters

Product Information Origin Tianjing, China Series U Series Brand MSK Cutting Edge Form Helical Structure Ball Diameter (Mm) 3 Material Carbide Minimum Cutting Diameter At Th […]

Carbide Roland CAD/CAM Burs

Product Information Origin Tianjing, China Brand MSK Number Of Blades 4 Product Name Dental Special 4-Blade End Mill Model D Number Of Blades Z X N L d 4TD2060HB 2 4 […]

HP Deburring Carbide Burs

Product Information Brand MSK Material Tungsten Steel Model Grinding Head Custom Processing Yes Feature: The dental grinding head is made of tungsten steel with stabl […]

Dental CAD/CAM Milling Burs

Product Information Origin Tianjing, China Material Stainless Steel Brand MSK Applicable Machine Tools A Variety Of Options Custom Processing Yes Whether To Coat No Is It a […]

Supply Roland DLC Zirconia Burs

Product Information Origin Tianjing, China Series Dental Bur Brand MSK Cutting Edge Form 2 Blade/3 Blade Ball Diameter (Mm) 0.6, 1, 2 Material Very Fine Grained Cemented Car […]

Diamond Bur Ball Round

Product Information Product Name Dental 4-Flute Ball End Mill Brand MSK Model D Number Of BladesZ X N L d 4BTD2060 2 4 6 6 50 3 4BTD2010 2 4 6 10 50 3 4BTD2016 2 4 6 […]

Post time: 2023-07-06