If you use zirconia, cobalt chrome, titanium, nanocomposites, polymethylmethacrylate or wax, MSK has the best milling cutter for the dental material you want to machine. Coatings specially adapted for this type of material ensure the highest surface quality and long tool life.

1.Zirconia Ball Nose End Mills

Microcrystalline Carbide End Mills

double slot

30° up-cut helix

center cut

Toric groove

Shank without clamping surface DIN 6535-HA

For machining of non-fired high performance ceramics such as zirconia and alumina.

2.Cobalt Chrome/Titanium Ball End Mills

Microcrystalline Carbide End Mills

double slot

30° up-cut helix

center cut

Toric groove

Shank without clamping surface DIN 6535-HA

For machining of cobalt-chromium alloys, titanium metals and titanium alloys.

3.Spherical milling cutter for zirconium dioxide/cobalt-chromium/titanium

Microcrystalline Carbide End Mills

double slot

Spherical 270°

center cut

Toric groove

Shank without clamping surface DIN 6535-HA

This spherical milling cutter is particularly suitable for finishing undercut areas without turning or tilting the clamped material.

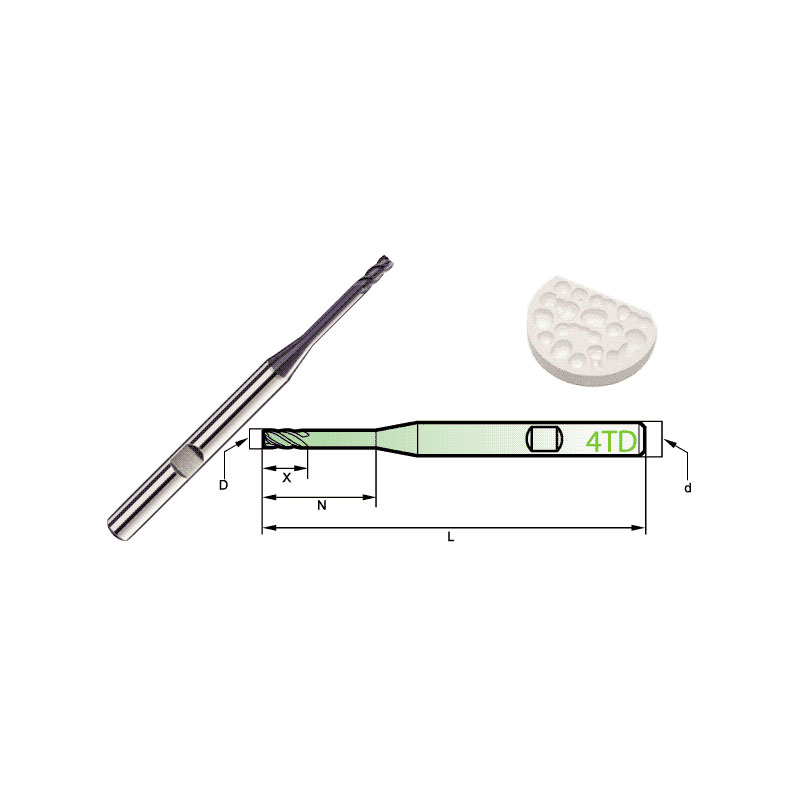

4.Nanocomposite/Advanced Materials Milling Cutter

Microcrystalline Carbide End Mills

double slot

30° up-cut helix

center cut

Toric groove

Shank without clamping surface DIN 6535-HA

For machining of nanocomposites/advanced blanks.

5.PMMA/Wax Ball End Mills

Microcrystalline Carbide End Mills

double slot

30° up-cut helix

center cut

Toric groove

Shank without clamping surface DIN 6535-HA

For machining of acrylic polymers and wax blanks

The polished flutes of this cutter are designed for soft material milling for clean, burr-free milling results. Spacious tool flutes ensure efficient chip removal.

Related Product

Dental CAD/CAM Milling Burs

Product Information Origin Tianjing, China Material Stainless Steel Brand MSK Applicable Machine Tools A Variety Of Options Custom Processing Yes Whether To Coat No Is It a […]

Carbide Roland CAD/CAM Burs

Product Information Origin Tianjing, China Brand MSK Number Of Blades 4 Product Name Dental Special 4-Blade End Mill Model D Number Of Blades Z X N L d 4TD2060HB 2 4 […]

Step Bur Milling Bur Grinder for Glass Cerami

Product Information Origin Tianjing, China Shank Diameter 1.8 (mm) Brand MSK Scope Of Application CEREC3 Grinding Equipment Material Stainless Steel/Carbide Main Sales Areas […]

Supply Roland DLC Zirconia Burs

Product Information Origin Tianjing, China Series Dental Bur Brand MSK Cutting Edge Form 2 Blade/3 Blade Ball Diameter (Mm) 0.6, 1, 2 Material Very Fine Grained Cemented Car […]

Diamond Coating Round Diamond Cutters

Product Information Origin Tianjing, China Series U Series Brand MSK Cutting Edge Form Helical Structure Ball Diameter (Mm) 3 Material Carbide Minimum Cutting Diameter At Th […]

HP Deburring Carbide Burs

Product Information Brand MSK Material Tungsten Steel Model Grinding Head Custom Processing Yes Feature: The dental grinding head is made of tungsten steel with stabl […]

Diamond Bur Ball Round

Product Information Product Name Dental 4-Flute Ball End Mill Brand MSK Model D Number Of BladesZ X N L d 4BTD2060 2 4 6 6 50 3 4BTD2010 2 4 6 10 50 3 4BTD2016 2 4 6 […]

Post time: 2022-06-02