When it comes to performing dental procedures, having the correct round bur size is absolutely essential. From reshaping tooth enamel to eradicating decay, these burs serve many purposes. It is key for practitioners to be aware of the diverse array of sizes available in order to make an informed decision and choose the appropriate tool for the task at hand.

For dentists, the commonly used round bur sizes are the FG, FG-G, and FG-P varieties. All of these feature diamond coatings that help with the process of forming, shaping, and fine-tuning enamel. The FG is the smallest of the bunch and works best for sections that require detailed cutting. Larger than the FG is the FG-G, designed to trim and polish larger portions of enamel. Last but not least, the largest bur size is the FG-P which brings more force to bear for aggressive enamel sculpting.

Variety isn’t lacking when it comes to burs – in addition to the standard sizes, specialty versions are available as well. These include tapered burs ideal for crafting mellow transitions between distinct areas of enamel, serrated burs designed to reduce the period of time necessary for getting rid of substantial decay, and pointed burs which can be used to craft little openings in enamel.

When it comes time to choose the suitable round bur size for a dental procedure, several elements must be taken into consideration. The job at hand dictates the size of the bur required, ranging from a small FG size for trimming and buffing minute sections of enamel to a larger FG-P size for more intense shaping and sanding. Similarly, the hardness of the enamel also meshes into this, where softer enamel may require larger burr while denser enamel necessitates a smaller one.

With elbow to the grindstone, meticulous consideration should be taken into account when selecting the appropriate round bur size; think of the handpiece in use. In some cases, handpieces may be unable to accommodate a bigger bur, hence it is of paramount importance to confirm that the size of the chosen bur fits with the handpiece utilized.

Along with the traditional round bur sizes, additional tools are helpful for detailed operations. Tungsten carbide burs are suited for cutting the tougher surfaces like ceramics or metal, while stainless steel burs specialize in grinding and polishing tasks. Last but not least, diamond-coated burs mark their area of expertise by cutting and refining enamel.

Mastery of the various round bur sizes is of utmost importance in the field of dentistry. Picking the right size for a given procedure contributes to the efficient and successful completion of a task. Therefore, it is essential for dentists to conduct thorough research on the different shapes, sizes, and types of burs to ensure that they are investing in the correct tool.

Teeth are routinely sculpted and chiseled with dental round bur sizes – an essential device for dentists. From bridges to crowns and fillings, these rotating cutting tools are designed to perform a wide range of modifications, from removing decay to formulating shapes to fit a tooth’s specific needs. Just like toothpicks, burs come in different sizes and shapes, so they can be tailored according to the task at hand.

The diameter of a dental bur varies from 0.6mm to 1.2mm, determining its size and, consequently, the amount of material that it can eliminate and the exactness with which it can be formed. Generally speaking, a diminutive bur is employed for reducing smaller amounts of material, while larger burs are fitted to removal of generous portions.

When considering the various options for shaping and cutting, there is a broad range of dental burs available – each distinguished by its unique features. While some are crafted for tougher surfaces, like porcelain, others specialize in softer structures, such as composite. In addition, some offer extra precision in their techniques while others are more suitable for more general cutting.

The precise and efficient shaping of dental materials requires a variety of bur sizes and shapes. The most widely used shape in dentistry is the round bur, which are available in sizes from 0.6mm to 1.2mm. The size of the bur is integral in determining the accuracy of the trimming process and the volume of material that it can effectively remove, as smaller burs generally work with less material to provide more precise cuts, while their bigger counterparts are capable of removing larger pieces for more extensive modifications.

It’s paramount to pick a dental bur that is optimized for the material that needs cutting or shaping. Generally, burs made for tougher elements like porcelain tend to be more diminutive than those created for yielding substances such as composite. Thus, selecting a bur that is apt for the purpose is key.

The shank is a vital factor of the bur that should not be overlooked. It attaches the bur to the hand piece, but the compatibility must be considered. Ensuring that your chosen bur corresponds with the type of hand piece you are using is essential. No matter how size and shape-specific your bur is, an incompatible shank might lead to a chaotic scene during operations.

Accurate and efficient dental work starts with selecting the perfect round bur size. The size of your bur largely dictates the amount of material that you can remove. A larger bur enables you to remove larger amounts, whilst smaller burs excel at precise cuts. Moreover, selecting the right shank for your hand piece is paramount, and it is equally important to choose burs designed specifically for the material you’re dealing with. By picking the correct bur, you can ensure your dental work has amazing results and is of top-notch quality.

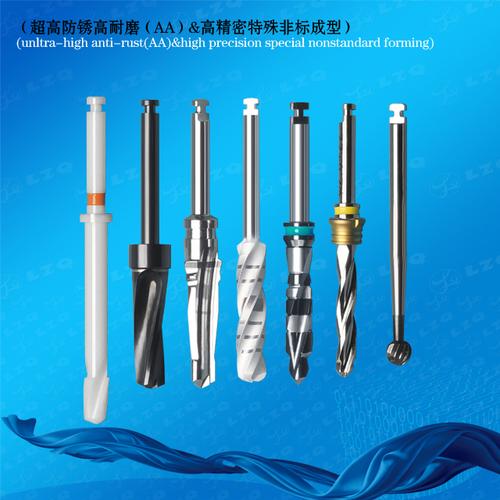

Related Product

Supply Roland DLC Zirconia Burs

Product Information Origin Tianjing, China Series Dental Bur Brand MSK Cutting Edge Form 2 Blade/3 Blade Ball Diameter (Mm) 0.6, 1, 2 Material Very Fine Grained Cemented Car […]

Diamond Bur Ball Round

Product Information Product Name Dental 4-Flute Ball End Mill Brand MSK Model D Number Of BladesZ X N L d 4BTD2060 2 4 6 6 50 3 4BTD2010 2 4 6 10 50 3 4BTD2016 2 4 6 […]

Step Bur Milling Bur Grinder for Glass Cerami

Product Information Origin Tianjing, China Shank Diameter 1.8 (mm) Brand MSK Scope Of Application CEREC3 Grinding Equipment Material Stainless Steel/Carbide Main Sales Areas […]

Dental CAD/CAM Milling Burs

Product Information Origin Tianjing, China Material Stainless Steel Brand MSK Applicable Machine Tools A Variety Of Options Custom Processing Yes Whether To Coat No Is It a […]

HP Deburring Carbide Burs

Product Information Brand MSK Material Tungsten Steel Model Grinding Head Custom Processing Yes Feature: The dental grinding head is made of tungsten steel with stabl […]

Diamond Coating Round Diamond Cutters

Product Information Origin Tianjing, China Series U Series Brand MSK Cutting Edge Form Helical Structure Ball Diameter (Mm) 3 Material Carbide Minimum Cutting Diameter At Th […]

Carbide Roland CAD/CAM Burs

Product Information Origin Tianjing, China Brand MSK Number Of Blades 4 Product Name Dental Special 4-Blade End Mill Model D Number Of Blades Z X N L d 4TD2060HB 2 4 […]

Post time: 2023-07-17