As a fundamental component of dental work, sky burs are cutting implements that rotate to influence the shape and finish of teeth in various ways. Commonly referred to as ‘dental burs’, these tools come in varying shapes and sizes according to the type of precisesion-work required. Without sky burs, dentists would be unable to efficiently carve hard tissues like teeth and other structures.

Crafted with precision, sky burs are typically constructed using Stainless Steel, carbide, and tungsten to produce a bur that can hone and form teeth. Diamond coating forms the cutting head, which is engineered to survive and thrive why cutting through tough surfaces such as bone and teeth. These burs are used for a myriad of purposes including shaping and constructing teeth, producing smooth surfaces after cutting, as well as polishing the tooth post-operation.

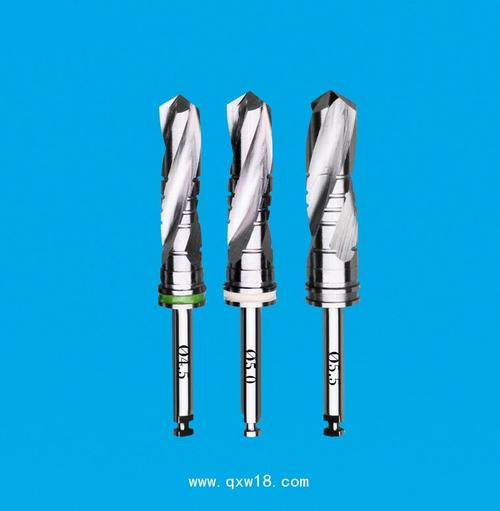

Sky burs come in numerous shapes, sizes, and cutting heads that fulfill different needs. For instance, a round bur is used for carving the enamel; a fissure bur for crafting crevices in the teeth; a cone bur for forming teeth; and a flat bur to create even planes. Moreover, sky burs can rid of the decaying matter from the teeth and give them a smooth finish.

To avoid any adverse effects on the teeth, sky burs should be used with caution and at a steady speed. It is also imperative that sky burs are applied in the direction of the tooth’s surface to prevent any possible harm to the enamel. In order for sky burs to remain operational, they must be routinely inspected and replaced when they become too dull or worn.

No matter which type of sky bur is being employed, the most suitable variety should be chosen for the particular task at hand. An inappropriate choice can result in unsatisfactory outcomes and should be avoided. Moreover, using an ideal lubricant while handling a sky bur can help decrease friction and heat produced by the bur, thus preserving its longevity.

Dental professionals regard sky burs as essential for forming and sculpting teeth during dental procedures. Present in a variety of sizes, shapes, and cutting heads, these tools are thoughtfully constructed to meet the requirements of specific dental operations. For the best outcome, dental experts urge that correct usage and caution be exercised while utilizing sky burs which can assist in safeguarding the dental health and appearance of teeth.

In the realm of dentistry, dental sky burs hold a position of prominence. Also known simply as dental burs, these tiny tools are employed in dental operations to shape, refine, and eliminate materials from teeth. Depending on their use, this may include elements like enamel, dentin, and cementum; in other cases, dental burs serve to groom and arrange surfaces with the intention of bonding and restoration. The majority of these units are made with either stainless steel or tungsten carbide, while varying contours and sizes ensure that there is a suitable dental bur for every task.

Since its inception in the early 20th century, the dental bur has revolutionized dentistry as we know it. Initially developed to help shape and prepare teeth for restoration or repair, this tool is now an indispensable asset in virtually all dental treatments, from cavity filling to crown installations.

There are numerous burs utilized in dentistry, ranging from round burs used primarily to excavate cavities and prep teeth for restorations, to taper burs fashioned for crafting small grooves and slots, diamond burs to cut and form harder surfaces like enamel, and flame burs to polish and refine teeth.

It is essential to carefully select the right dental bur to be used for a specific task. The wrong type of bur can cause harm to the tooth or the patient, thus always use a bur that is fitting for the task at hand. Moreover, make sure to use an appropriate speed and pressure level when handling any bur, since too much pressure can result in frequent wear and tear.

Proper bur selection is essential for successful dental treatment procedures. One must ensure that the size and shape of the selected bur is suitable for the task at hand, with larger burs being utilized on bigger cavities, and smaller ones for more delicate operations. To guarantee optimal performance, it is important to ensure that burs remain sharpened regularly.

To ensure your safety while working with dental burs, remember to put on gloves, face protection, and goggles. This gear will help you ward off any unwanted substances that may be released as you work. Additionally, use of a lubricant is recommended in order to make sure your bur is working at its peak efficiency and to minimize friction.

For any dental practitioner, a collection of burs is of great importance. With a range of sizes and shapes, these tools are ideal for trimming, smoothing, and removing dental material from teeth. Selecting the best suited bur for the job, operating at the optimal speed and force, and wearing appropriate safety gear is essential for successful use and maintenance. The right burs can be incredibly beneficial to any dentist’s practice when employed correctly.

Related Product

Dental CAD/CAM Milling Burs

Product Information Origin Tianjing, China Material Stainless Steel Brand MSK Applicable Machine Tools A Variety Of Options Custom Processing Yes Whether To Coat No Is It a […]

Diamond Bur Ball Round

Product Information Product Name Dental 4-Flute Ball End Mill Brand MSK Model D Number Of BladesZ X N L d 4BTD2060 2 4 6 6 50 3 4BTD2010 2 4 6 10 50 3 4BTD2016 2 4 6 […]

Carbide Roland CAD/CAM Burs

Product Information Origin Tianjing, China Brand MSK Number Of Blades 4 Product Name Dental Special 4-Blade End Mill Model D Number Of Blades Z X N L d 4TD2060HB 2 4 […]

Step Bur Milling Bur Grinder for Glass Cerami

Product Information Origin Tianjing, China Shank Diameter 1.8 (mm) Brand MSK Scope Of Application CEREC3 Grinding Equipment Material Stainless Steel/Carbide Main Sales Areas […]

HP Deburring Carbide Burs

Product Information Brand MSK Material Tungsten Steel Model Grinding Head Custom Processing Yes Feature: The dental grinding head is made of tungsten steel with stabl […]

Diamond Coating Round Diamond Cutters

Product Information Origin Tianjing, China Series U Series Brand MSK Cutting Edge Form Helical Structure Ball Diameter (Mm) 3 Material Carbide Minimum Cutting Diameter At Th […]

Supply Roland DLC Zirconia Burs

Product Information Origin Tianjing, China Series Dental Bur Brand MSK Cutting Edge Form 2 Blade/3 Blade Ball Diameter (Mm) 0.6, 1, 2 Material Very Fine Grained Cemented Car […]

Post time: 2023-08-03