Every dentist and oral surgeon knows that dental tooth extraction forceps are an indispensable component of their toolkit. From slender to broad, these instruments allow for simple and secure grasping and removal of teeth from the jawbone. With precision crafted strength, such forceps can extract even the most entrenched tooth without doing harm to adjacent tissue.

Stainless steel forceps of various sizes and shapes facilitate the extraction of teeth from the jawbone. The tips of the forceps are sharp, with curved blades and a handle that can be adjusted to fit any size. Grasping the tooth with precision, the forceps make sure to remove it from the jawbone safely and without damage.

Designed for the purpose of uprooting teeth, “elevator” forceps are the most widely used forceps when it comes to extractions. In coordination with another extraction instrument, these forceps are able to apply a sufficient amount of force needed to dislodge a tooth from its socket. Having done that, the elevator forceps can then be utilized to carefully lift the tooth from its placement in the jawbone.

When confronted with a tooth that is stubbornly wedged in the jawbone, forceps come to the rescue! By carefully applying subtle pressure and adeptly maneuvering the forceps, the tricky tooth can be eased out of its socket before being completely extracted.

Besides elevators, a few additional styles of dental extraction forceps exist. The “periosteal” forceps are put into action to grip and take away items of bone that may exist in the jawbone. These forceps are also utilized for releasing teeth that are entrenched in the jawbone.

The “bone block” forceps come into play when a tooth needs to be extracted, but a bigger piece of bone is getting in the way. By utilizing this tool, it is possible to remove the obstructing pieces of bone from the jawbone and free up the way for the tooth to be taken out.

Specially designed to pry away a stubborn and embedded tooth, extraction forceps are equipped with two curved blades which firmly ensnare the tooth before it is carefully removed from the jawbone.

For any dental operation requiring the extraction of teeth, the use of specialized forceps is absolutely essential. These particular instruments, crafted in various shapes and sizes, are meant to safely and painlessly draw out the tooth from its root embedded in the jawbone. Forceps can be used either solo or combined with other dental tools to guarantee the extraction process goes smoothly and is successful.

Maintaining dental health often requires tooth extraction. This is usually necessary to remove a decaying tooth or create extra space for orthodontic treatment. The careful application of specialized dental instruments makes the extraction process much safer and more effective. Among these instruments, dental forceps are essential for successful extraction of the damaged tooth.

For dental procedures, forceps are a key tool used to safely remove teeth. Crafted from stainless steel, they come in various shapes and sizes that allow for flexibility in grasping each individual tooth. Several rounded prongs at the end of the forceps are used to hold and secure the tooth, while a firm but gentle pull will ultimately extract it.

Various sizes of dental extraction forceps are available, each of which can be used for different purposes. Elevators are handy for lifting the tooth up before extracting it, whereas beaks help to break up the gum tissue bound around the tooth. Ratchets can be used to secure a grip on the tooth and effortlessly generate leverage for removal. Smaller or larger forceps may be necessary, depending on the size of the particular tooth.

When dealing with forceps, safety should be the highest priority. Proper safeguards must be put in place, such as wearing gloves and protective eyewear while securely gripping the tool. Additionally, the tool should only be used for its intended purpose; otherwise, it could lead to an unintended consequence.

During an extraction process, the right type of forceps needs to be employed for optimal results. Utilizing device other than that designed for the job can lead to catastrophic results such as broken or lost teeth. Such an outcome can result in significant tissue damage in the vicinity.

To prevent diseases from spreading, it is essential to sterilize the dental forceps after each tooth removal. After use, clean the forceps with a sanitizing solution, then rinse and dry them off before putting them away in a tidy and moisture-free container. This will ensure a safe and hygienic environment for your patients.

For a successful tooth extraction process, dental professionals cannot go without the appropriate forceps. These specially designed tools are an integral part of all dental treatments. To ensure patient protection and optimal results, procedures must be carried out with consideration for safety regulations and the care of the forceps themselves.

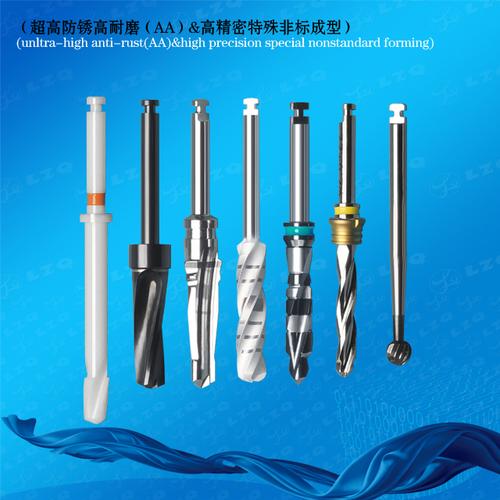

Related Product

Step Bur Milling Bur Grinder for Glass Cerami

Product Information Origin Tianjing, China Shank Diameter 1.8 (mm) Brand MSK Scope Of Application CEREC3 Grinding Equipment Material Stainless Steel/Carbide Main Sales Areas […]

HP Deburring Carbide Burs

Product Information Brand MSK Material Tungsten Steel Model Grinding Head Custom Processing Yes Feature: The dental grinding head is made of tungsten steel with stabl […]

Diamond Bur Ball Round

Product Information Product Name Dental 4-Flute Ball End Mill Brand MSK Model D Number Of BladesZ X N L d 4BTD2060 2 4 6 6 50 3 4BTD2010 2 4 6 10 50 3 4BTD2016 2 4 6 […]

Diamond Coating Round Diamond Cutters

Product Information Origin Tianjing, China Series U Series Brand MSK Cutting Edge Form Helical Structure Ball Diameter (Mm) 3 Material Carbide Minimum Cutting Diameter At Th […]

Dental CAD/CAM Milling Burs

Product Information Origin Tianjing, China Material Stainless Steel Brand MSK Applicable Machine Tools A Variety Of Options Custom Processing Yes Whether To Coat No Is It a […]

Supply Roland DLC Zirconia Burs

Product Information Origin Tianjing, China Series Dental Bur Brand MSK Cutting Edge Form 2 Blade/3 Blade Ball Diameter (Mm) 0.6, 1, 2 Material Very Fine Grained Cemented Car […]

Carbide Roland CAD/CAM Burs

Product Information Origin Tianjing, China Brand MSK Number Of Blades 4 Product Name Dental Special 4-Blade End Mill Model D Number Of Blades Z X N L d 4TD2060HB 2 4 […]

Post time: 2023-07-16