When it comes to cutting and grinding a variety of materials, diamond carbide bur is the tool of choice for industries ranging from automotive to medical. This cutting instrument is crafted from a mix of diamond and carbide, which provides remarkable and unmatched cutting strength. The combination makes diamond carbide bur a standout for its superior capacity in grinding and cutting.

Outshining all hard materials known to man, the noble diamond plays a starring role in combination with its steely companion, carbide. This duo gives the diamond carbide bur the capacity to cut and grind even the toughest substances. Moreover, its remarkable speed offers a significant advantage for applications requiring expedient results.

A diamond carbide bur is a staple in numerous industrial settings. Auto-mechanics put it to use for cutting and grinding metal components, while surgeons use it to craft vital medical equipment. This bur is also a must-have tool in the construction industry, as it is used to cut and refine concrete and other masonry materials.

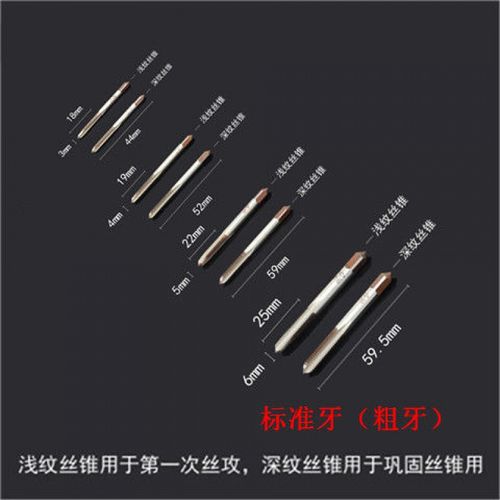

A range of shapes and sizes of diamond carbide bur awaits selection, from rounded to squared, diamond to cone shaped – the perfect tool for a plethora of applications and material thicknesses. Variance in bur grits allows one to consider both speed and desired work finish before purchase.

It is absolutely essential to don protective eyewear and gloves if you plan on making use of a diamond carbide bur. Just like any other power tool, employing a diamond carbide bur may generate sparks and dust that could be detrimental to your well being. Additionally, it is recommended that the appropriate lubricant be employed with the bur to guarantee a secure and efficient operation.

If utilizing a diamond carbide bur, cleanliness and keenness are of the utmost importance. Clear off any dirt and waste that has built up after each utilization to preserve the bur. Furthermore, on a regular basis, hone the bur in order to guarantee it is cutting adequately and productively.

A diamond carbide bur truly stands out among its cutting tool competition; it is highly versatile and capable of delivering remarkable results. When used correctly, this equipment can increase productivity, efficiency, and accuracy across a variety of industrial and medical projects. Its superior cutting and grinding abilities have made the diamond carbide bur a go-to choice for these industries.

The Multi-Purpose Power of a Diamond Carbide Bur

Diamond carbide bur is a valuable instrument that can be employed across various sectors and for a whole multitude of functions – from polishing metal to dental procedures. A combination of diamond and carbide particles gives the tool strength, meaning it is commonly found in car workshops, aeronautics, and hospitals.

A diamond carbide bur is a formidable rotary burr, designed to provide strength and longevity while performing exclusive modifications on an array of substances, for instance, plastic, wood, and metal. This ramified tool comprises of diamond particles that ensure a rigorous abrasion and carbide particles to fortify robustness – integrating the figures to produce one high-functioning tool. The dual components provide a premium option for a broad selection of projects.

The tiny diamond-particles of the bur create an intensified abrasive force, rendering this tool suitable for a vast array of metalworking projects. Eligible materials include stainless steel, aluminum, and brass, while widespread tasks include polishing and finishing, as well as surface cleaning and styling intricate shapes.

The bur is an optimal selection for tasks with exacting demands on the longevity and robustness of a tool; this is due to the resinous carbide particles which give the bur its excellent performance characteristics. Its qualities make it the go-to-choice for the production of aircraft components in the aerospace industry, as well as for automobile engine parts in the automotive sector.

For decades, diamond carbide bur has been recognized as a go-to tool in the industrial sector; however, its application is far more diverse than that. It has become an essential part of the medical field, serving various purposes when it comes to dental health and standards. From its use in preparing dental implants and crafting custom dental crowns, to cutting and shaping gums and polishing teeth – diamond carbide bur is a versatile tool that helps medical professionals and patients enjoy quality care.

When it comes to working with wood, diamond carbide bur is a go-to tool. From sculpting, crafting, and etching detailed patterns and designs – to forming and refining wood surfaces, it is a reliable choice for many projects. It has been considered a must-have in the woodworker’s arsenal for its versatility.

An ideal choice for a variety of projects, a diamond carbide bur is a highly dependable tool. It is a combination of diamond and carbide particles, resulting in enhanced abrasion, potency, and longevity. This makes it the go-to tool for everything from metalwork to medical procedures.

Related Product

HP Deburring Carbide Burs

Product Information Brand MSK Material Tungsten Steel Model Grinding Head Custom Processing Yes Feature: The dental grinding head is made of tungsten steel with stabl […]

Dental CAD/CAM Milling Burs

Product Information Origin Tianjing, China Material Stainless Steel Brand MSK Applicable Machine Tools A Variety Of Options Custom Processing Yes Whether To Coat No Is It a […]

Carbide Roland CAD/CAM Burs

Product Information Origin Tianjing, China Brand MSK Number Of Blades 4 Product Name Dental Special 4-Blade End Mill Model D Number Of Blades Z X N L d 4TD2060HB 2 4 […]

Supply Roland DLC Zirconia Burs

Product Information Origin Tianjing, China Series Dental Bur Brand MSK Cutting Edge Form 2 Blade/3 Blade Ball Diameter (Mm) 0.6, 1, 2 Material Very Fine Grained Cemented Car […]

Diamond Bur Ball Round

Product Information Product Name Dental 4-Flute Ball End Mill Brand MSK Model D Number Of BladesZ X N L d 4BTD2060 2 4 6 6 50 3 4BTD2010 2 4 6 10 50 3 4BTD2016 2 4 6 […]

Step Bur Milling Bur Grinder for Glass Cerami

Product Information Origin Tianjing, China Shank Diameter 1.8 (mm) Brand MSK Scope Of Application CEREC3 Grinding Equipment Material Stainless Steel/Carbide Main Sales Areas […]

Diamond Coating Round Diamond Cutters

Product Information Origin Tianjing, China Series U Series Brand MSK Cutting Edge Form Helical Structure Ball Diameter (Mm) 3 Material Carbide Minimum Cutting Diameter At Th […]

Post time: 2023-07-18