For centuries, milling bur arum has long been incorporated into the practice of turning grains into flour for consumption. In a process that has since transcended time, this traditional technique of grinding remains a staple across many cultures and nations. With this article, we look to explore the practice of milling bur arum; offering an overview of its history, benefits, and even its current applications.

Milling bur arum holds a special place in history, having been employed by the ancient Egyptians as early as the first century. With a hefty hand-powered millstone, grains were turned into flour to form the bread that brokefasted many centuries ago. As the Romans adopted and popularized the same technique, the entire continent of Europe saw milling bur arum emerge as a cornerstone of everyday life, seen flourishing in many villages and towns across the kingdoms of the Middle Ages.

Grains are crushed into a fine flour with the help of milling bur arum, which utilizes a motor-driven or hand-cranked arrangement of two stones. This traditional milling process is still used in various regions of the world that lack access to more advanced milling methods. Created through grinding and splitting, the flour can be put to a number of culinary uses, such as cake-baking, cooking, and beyond.

Bur arum milling has the edge over traditional modernisation in that it safeguards the nutrients locked within grains. These retain a greater abundance of vitamins, minerals, and fibre when compared to products engineered via contemporary technology. As such, flour produced by bur arum milling is noticeably healthier than other alternatives on the market.

When milling bur arum, a much finer flour is produced as opposed to other milling approaches. This finely-milled flour is especially suitable for baking and imparts a buoyant, airy texture to the finished product. Additionally, due to the delicate process of milling bur arum, the grains’ natural flavors are preserved, thus adding more flavor to the outcome.

Despite its age-old history, the practice of milling bur arum flour is still prevalent in certain areas around the world. It is especially popular in rural locales, without access to more current forms of milling technology. Similarly, its popularity also grows in places without access to electricity or other power sources necessary to run modern milling machines.

For centuries, milling bur arum has been a preferred technique for milling grains, a practice that continues today in parts of the globe where modern equipment is not available. Renowned for its efficiency, this old-fashioned method guarantees to preserve the nutrients of grains while producing a superior and nutritious flour. Therefore, milling bur arum is an attraction for those looking to generate a healthier, more pronounce-tasting product.

Since the distant past, the art of milling Bur Arum has held an esteemed place in fabric-making traditions. This labor-intensive process is performed by hand to fashion a look and feel that can’t be replicated in any other way. In this article, we’ll shine a spotlight on the backstory of Millling Bur Arum, take an up-close look at the special technique needed to produce it, and consider its current applications in modern life.

Exploring the Ancient Art of Milling Bur Arum

In Southeast Asia, Milling Bur Arum is a centuries-old weaving process that produces high-quality fabric. Originating from the Sanskrit term “bharam” which means “strip” or “band”, this traditional Thai technique was first designed to fulfil the need for fabrics for signature clothing and has since been adopted in wide use. The impressive output of this method is an exquisitely finished material that hides endless possibilities of creation.

Creating Bur Arum fabric is a lengthy and intricate process that calls for a craftsman’s touch. Expert tatters skillfully pick and connect thread-thin threads, winding and weaving them together. This process can stretch on for days to form the remarkable cloth.

The Art of Grinding Bur Arum

In the art of milling Bur Arum, thin strips of fabric are delicately intertwined into a mesmerising fabric. To create this texture, the pieces must be slowly and painstakingly woven together, sometimes allowing up to several days for completion. Furthermore, the strips are coloured in remarkable hues that blend together in a magical dance when woven. When each thread unites with its neighbour, a vibrant and unique pattern appears; a combinations of colours playfully combined into one piece, creating a marvellous textile that’s unlike any other.

After the intricate weaving is done, the fabric is made stiffer by treating it with a starch or sizing. This enhances its structure and sturdiness to enable more seamless working. Afterwards, it is washed, dried, and cut to reach its desired size and shape.

Exploring the Benefits of Milling Bur Arum

Crafted from ancient weaving techniques, the Bur Arum fabric is a unique material with countless utilizations. Whether to clothe oneself in traditional Thai garments or to decorate a home with tablecloths, curtains, and cushion covers, Milling Bur Arum is the perfect choice.

Weaving the fabric miraculously transforms it into fashionable accessories like handbags, purses and scarves. It is also used to make some classic instruments, such as the Thai khim. And; its lightweight and durable structure makes it perfect for creating pieces of jewelry.

Through the ancient technique of Milling Bur Arum, artisans can create a strikingly original texture-rich fabric. This unique combination of strips of cloth holds up better than most regular garments, perfect for apparels, accessories, along with home dcor pieces, and even musical instruments. Delicately lightweight and surprisingly durable, this timeless textile has captured the imagination of many over centuries.

Related Product

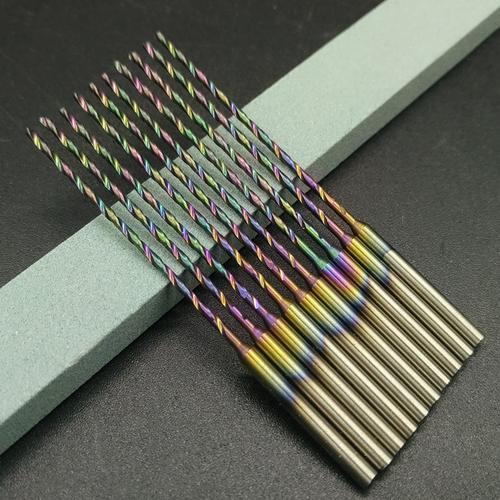

HP Deburring Carbide Burs

Product Information Brand MSK Material Tungsten Steel Model Grinding Head Custom Processing Yes Feature: The dental grinding head is made of tungsten steel with stabl […]

Dental CAD/CAM Milling Burs

Product Information Origin Tianjing, China Material Stainless Steel Brand MSK Applicable Machine Tools A Variety Of Options Custom Processing Yes Whether To Coat No Is It a […]

Diamond Bur Ball Round

Product Information Product Name Dental 4-Flute Ball End Mill Brand MSK Model D Number Of BladesZ X N L d 4BTD2060 2 4 6 6 50 3 4BTD2010 2 4 6 10 50 3 4BTD2016 2 4 6 […]

Supply Roland DLC Zirconia Burs

Product Information Origin Tianjing, China Series Dental Bur Brand MSK Cutting Edge Form 2 Blade/3 Blade Ball Diameter (Mm) 0.6, 1, 2 Material Very Fine Grained Cemented Car […]

Step Bur Milling Bur Grinder for Glass Cerami

Product Information Origin Tianjing, China Shank Diameter 1.8 (mm) Brand MSK Scope Of Application CEREC3 Grinding Equipment Material Stainless Steel/Carbide Main Sales Areas […]

Diamond Coating Round Diamond Cutters

Product Information Origin Tianjing, China Series U Series Brand MSK Cutting Edge Form Helical Structure Ball Diameter (Mm) 3 Material Carbide Minimum Cutting Diameter At Th […]

Carbide Roland CAD/CAM Burs

Product Information Origin Tianjing, China Brand MSK Number Of Blades 4 Product Name Dental Special 4-Blade End Mill Model D Number Of Blades Z X N L d 4TD2060HB 2 4 […]

Post time: 2023-07-11