Dentists rely on dental extraction forceps to extract teeth from the patient’s mouth. These devices, crafted from stainless steel, are comprised of two pieces: a handle and an inner blade. Both sections work in collaboration to remove a tooth; the blade slips around and takes hold of it, while the handle provides the leverage to pull it out. Furthermore, using pressure on the handle can cause the forceps to rotate and loosen the tooth from its surrounding bone and tissue.

With diverse shapes and sizes, dental extraction forceps are devised to conveniently remove teeth depending on their particular type. Generally, universal forceps are chosen for extracting any kind of tooth. Nevertheless, others structured for specific teeth – including incisors, canines, premolars and molars – are available as well. Each type of forceps is custom-made to precisely fit the tooth they are meant to extract in a secure and effective way.

Dentists must take care in handling forceps when extracting teeth to ensure the safety and stability of the surrounding tissue. With precision and care, the forceps are positioned at just the right angle, followed by a steady amount of pressure on the handle to gently loosen the tooth from its socket. With each maneuver, dentists rotate the handle of the forceps to dislodge the tooth from its root until it is entirely freed and removed out of the patient’s mouth.

Expertise and accuracy are essential to maximizing patient comfort when using dental extraction forceps. While the procedure does offer its rewards, dentists should be aware of the associated dangers, such as causing harm to neighboring tissue, risking infection, and accidentally intensifying bleeding.

Physics experiments often require the use of forceps to measure the force and pressure of objects. By wrapping the forceps around a material, it’s possible to quantify how much pressure is being applied to the item and what kind of strength it possesses. This data is invaluable for those hoping to understand how force and pressure interact with each other and what different materials can handle. Though primarily employed in dentistry, dental extraction forceps can be adapted for use in such experiments.

Dentists are adept at using forceps to carefully extricate teeth from the mouth with minimal pain for the patient. Forceps come in an array of shapes and sizes, enabling the dentist to navigate their way around the particular tooth that is being removed. Moreover, they are also employed in physics experiments to assess the strength and pressure of objects. Summing up, dental extraction forceps are an invaluable asset for dentists and scientists alike.

More and more frequently, dentists are turning to the use of physics extraction forceps as a means of removing teeth – both permanent and temporary – from the jawbones, in a manner that lessens any potential harm to the patient. This cutting-edge equipment simplifies complex extractions that would be too challenging to attempt through the utilization of traditional methods. Ultimately, this remarkable tool allows for greater safety and comfort for those undergoing dental surgery.

Outfitted with a thin, flexible blade, physics extraction forceps provide dentists with a secure grip on the target tooth, enabling removal from the socket without harming surrounding tissue. Thanks to the extraction forceps’ design, dentists can precisely apply pressure to successfully and safety extract a tooth without damage.

With a range of shapes and sizes, forceps are the perfect choice for any dental procedure – whether large teeth or small. Constructed from stainless steel, forceps are highly durable and corrosion-resistant. Therefore, body techniques can be performed in various settings and for longer durations without the fear of future damage or wear-and-tear.

With physics extraction forceps, the dentist must be absolutely cautious ensuring that the blade does not bring any harm to the patient. Mandatory is the precise angle of insertion and exact amount of pressure for successful and safe tooth extraction. Moreover, extreme caution must be taken when executing pressure on the tooth as this could lead to breakage or cracking.

A tooth extraction requires the sanitization of the forceps handling the procedure prior to reuse. This makes certain that no contamination is transferred between patients and helps guarantee their wellbeing.

With the arrival of physics extraction forceps, dentists now possess a valuable asset for performing complex extractions with heightened accuracy and safety. This innovation in technology ensures that patients remain comfortable and free from harm during the removal of teeth, drastically reducing the amount of time it takes to complete each operation. Today, forceps are considered to be a must-have for any practitioner aiming to deliver a smooth and relaxed experience for each individual patient.

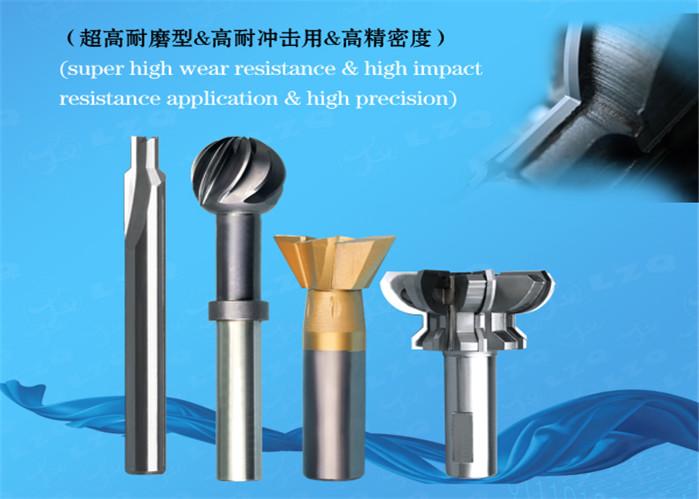

Related Product

Diamond Bur Ball Round

Product Information Product Name Dental 4-Flute Ball End Mill Brand MSK Model D Number Of BladesZ X N L d 4BTD2060 2 4 6 6 50 3 4BTD2010 2 4 6 10 50 3 4BTD2016 2 4 6 […]

Diamond Coating Round Diamond Cutters

Product Information Origin Tianjing, China Series U Series Brand MSK Cutting Edge Form Helical Structure Ball Diameter (Mm) 3 Material Carbide Minimum Cutting Diameter At Th […]

Step Bur Milling Bur Grinder for Glass Cerami

Product Information Origin Tianjing, China Shank Diameter 1.8 (mm) Brand MSK Scope Of Application CEREC3 Grinding Equipment Material Stainless Steel/Carbide Main Sales Areas […]

HP Deburring Carbide Burs

Product Information Brand MSK Material Tungsten Steel Model Grinding Head Custom Processing Yes Feature: The dental grinding head is made of tungsten steel with stabl […]

Dental CAD/CAM Milling Burs

Product Information Origin Tianjing, China Material Stainless Steel Brand MSK Applicable Machine Tools A Variety Of Options Custom Processing Yes Whether To Coat No Is It a […]

Carbide Roland CAD/CAM Burs

Product Information Origin Tianjing, China Brand MSK Number Of Blades 4 Product Name Dental Special 4-Blade End Mill Model D Number Of Blades Z X N L d 4TD2060HB 2 4 […]

Supply Roland DLC Zirconia Burs

Product Information Origin Tianjing, China Series Dental Bur Brand MSK Cutting Edge Form 2 Blade/3 Blade Ball Diameter (Mm) 0.6, 1, 2 Material Very Fine Grained Cemented Car […]

Post time: 2023-07-12