Tiny, cylindrical metal burs have long been the staple tool for shaping teeth at the dentist’s office. Yet lately there has been a growing trend toward plastic burs, which offer several advantages over traditional metal ones. Lower cost and improved handling are par for the course when it comes to plastic burs, but perhaps even more important is their ability to deliver a greater degree of safety for patients.

Depending on the type and purpose of the bur, dental burs can comprise of various materials such as polycarbonate, polypropylene, and polyethylene. For burs that need attention to detail and must be delicately formed, plastic made from polycarbonate are usually favored. Meanwhile, when the bur requires greater strength and durability, plastic created from polyethylene or polypropylene are employed.

Cost-effectiveness is one of the key benefits of plastic burs. Compared to metal burs, which can have a steep price tag, plastic burs are more attainable for dentists and other professionals. Plus, there’s a wide range of sizes, shapes, and styles available to meet each patient’s specific needs.

Compared to metal burs, plastic burs offer users enhanced control due to their weightlessness. Their lightness in construction allows for more precise and delicate movements, well-suited to creating intricate shapes and patterns. Furthermore, the lack of heat generation significantly decreases the risk of burning the patient’s teeth or gums.

Contrastingly to metal burs, plastic burs pose minimal risk to patients due to the fact that they are nonconductors of electricity and produce no sparks. Therefore, the risk of electric shock and burned skin is virtually eliminated with plastic burs, making them an ideal choice for patient safety.

While plastic burs have a plethora of advantages, there are some downsides to consider. Compared to their metallic counterparts, plastic burs tend to be less durable and need to be replaced more often. Furthermore, their precision is not as exacting as metal burs, making them ill-suited for projects that require intricate detail.

Dental burs made from plastic are an outstanding option for dentists and other experts looking to purchase a cost-effective, steady, and effortless bur. When comparing prices, they come much lower than those made from metal, increasing usability with their simpler control while providing reliable safety for the patient. Nevertheless, metal burs are more robust and accurate, making them unsuited for detailed work where precision is critical.

Plastic dental burs are essential instruments for dental practitioners, necessary for sculpting and chiselling tough materials. These mini sources of strength allow dentists to carry out a breadth of operations such as honing teeth, prepping cavities to accept fillings, and scraping away extra material. In short, plastic dental burs are a must-have in every dentist’s toolbox.

When crafting teeth restorations, dental technicians have an array of bur materials to consider. These include diamond, carbide, and plastic. Although diamond burs are the priciest option, they offer unparalleled precision and resilience. For more general-purpose shaping, carbide burs provide a more cost-effective solution. Meanwhile, their plastic counterparts are most suitable for polishing and smoothing operations; not to mention the fact that they come with a low price tag.

If you’re in the market for plastic dental burs, you’ll find a broad selection ranging from round to cone and cylinder shapes. The size of the dentistry tool is denoted by its diameter — a measurement usually expressed in millimeters (mm). Depending on the size, these burs may be excellent for polishing and refining, or tough enough for shaping and cutting.

Plastic dental burs serve as a multifunctional tool in dentistry, with applications that include shaping and contouring teeth, preparing cavities for filling, eliminating extra material when performing bridge or crown procedures, as well as cleaning up any excess composite used in cosmetic operations like installing veneers. In short, these efficient instruments are vital in creating the healthy and aesthetically pleasing smiles we all strive for!

The proper application of plastic dental burs is necessary for the avoidance of harm to the patient and a successful outcome of their dental procedure. Prior to engaging in the use of the bur, it is essential to examine it for signs of wear or breakage. Then, for the purpose of reducing heat and friction, it should be watered down or covered in a lubricating jelly. Lastly, it is critical to operate the bur at the ideal speed and with appropriate pressure so that damage to the tooth and surrounding areas is wholly prevented.

Once a dental procedure is completed, the bur should be scrupulously cleaned and sterilized. To help guard against possible contamination, plastic burs should stowed away in a dust-free, hygienic setting. Additionally, it is recommended to replace plastic burs often to ensure they retain their sharpness and efficacy.

Dentistry requires the use of plastic dental burs, which are relatively budget-friendly and resilient tools that have an array of applicable uses. Although these burs can be reliable, it is important to utilize them appropriately and replace them as needed in order to sustain their effectiveness and safety.

Related Product

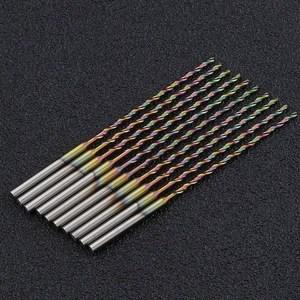

Dental CAD/CAM Milling Burs

Product Information Origin Tianjing, China Material Stainless Steel Brand MSK Applicable Machine Tools A Variety Of Options Custom Processing Yes Whether To Coat No Is It a […]

Supply Roland DLC Zirconia Burs

Product Information Origin Tianjing, China Series Dental Bur Brand MSK Cutting Edge Form 2 Blade/3 Blade Ball Diameter (Mm) 0.6, 1, 2 Material Very Fine Grained Cemented Car […]

Carbide Roland CAD/CAM Burs

Product Information Origin Tianjing, China Brand MSK Number Of Blades 4 Product Name Dental Special 4-Blade End Mill Model D Number Of Blades Z X N L d 4TD2060HB 2 4 […]

Step Bur Milling Bur Grinder for Glass Cerami

Product Information Origin Tianjing, China Shank Diameter 1.8 (mm) Brand MSK Scope Of Application CEREC3 Grinding Equipment Material Stainless Steel/Carbide Main Sales Areas […]

HP Deburring Carbide Burs

Product Information Brand MSK Material Tungsten Steel Model Grinding Head Custom Processing Yes Feature: The dental grinding head is made of tungsten steel with stabl […]

Diamond Coating Round Diamond Cutters

Product Information Origin Tianjing, China Series U Series Brand MSK Cutting Edge Form Helical Structure Ball Diameter (Mm) 3 Material Carbide Minimum Cutting Diameter At Th […]

Diamond Bur Ball Round

Product Information Product Name Dental 4-Flute Ball End Mill Brand MSK Model D Number Of BladesZ X N L d 4BTD2060 2 4 6 6 50 3 4BTD2010 2 4 6 10 50 3 4BTD2016 2 4 6 […]

Post time: 2023-07-15