Dental bur, used slowly, is a key technique for performing many operations in dental care, from clearing away decay to making room for fillings and creating the perfect structure for a crown. Slow speed bur dentistry shouldn’t be underestimated – it is an essential pillar of modern dentistry that needs to be recognised.

For precise, yet delicate dental procedures, dentists often utilize a low-speed bur. Made of a high-grade stainless steel, the bur typically runs at a rotating speed of 1,000-2,000 revolutions per minute (RPM) – significantly less than other high-powered drills that can reach speeds of up to 30,000 RPM. The slow rotation enables the dentist to properly regulate the material being eradicated and accurately shape the tooth with enhanced control.

After eliminating any decay, the dentist can get started on crafting the perfect fit for a crown or filling. To create an even plane, the tooth is carefully abraded with a slow speed bur dental, in order to create a stable and snug abode for the new material. This procedure ensures that the crown or filling will meld seamlessly with the tooth, providing an optimal and durable end result.

To make room for a filling, a dentist will employ a slow speed bur dental to vault the rotted area and customize it for its new purpose. Unlike typical drilling practices, this method proceeds slower and more accurately to make certain that the closure of the filling is secure and appropriate. This slow speed bur allows the dentist to construct a perfectly aligned cavity.

Slower speeds in dental practice are critical to ensure an exact and precise shaping of the affected area. This process makes it much easier to put on the crown or filling in its correct place and for that piece of work to last for a significant amount of time. Additionally, this approach lessens the likelihood of inadvertently causing injury to nearby teeth or gums.

Slower bur dental action has proven integral to accurate, superior dental work. From removing decay to preparing teeth for caps and creating adequate space for fillings, this type of careful excavation helps practitioners ensure that the end result is precise and durable. In other words, the speed of the process assists dentists in managing how much material they carve away and provides assurance that a crown or restoration can endure for quite a long while.

A Look into Low Speed-Bur Dental

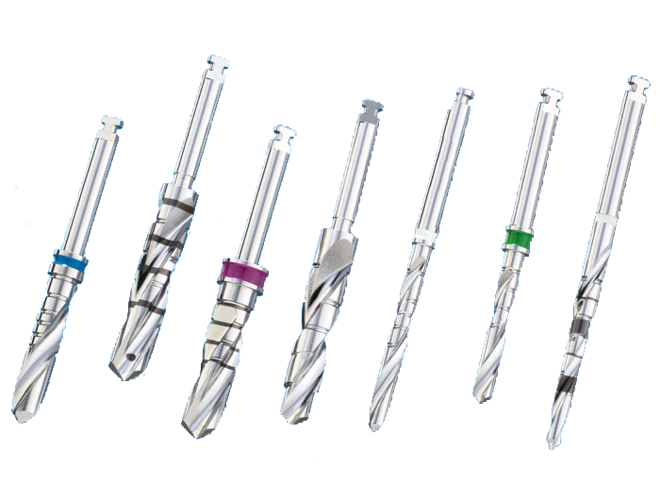

Dentists use slow speed burs dental to carry out numerous dental operations. Constructed from materials like diamond, metal, or ceramic, these tools can be utilized to shave and fashion hard structures including teeth. Provided in multiple dimensions and shapes, slow speed burs dental can be used for tasks like cleaning teeth, getting rid of plaque buildup, and cavity preparation.

Slow speed burs dental are the ideal way to go for efficient and economical dental work. The level of control involved in the cutting process means no damage is done to tissues, compared to other removal methods. Plus, you don’t have to put up with loud noise or disruptive vibrations – particularly beneficial for drills in delicate parts of the mouth.

Slow speed burs dental may be used with handpieces, air turbines, or even both, in order to optimise control over the speed and pressure of the cut. Such an approach enables a more accurate result while providing easier access in otherwise difficult-to-reach spots inside the mouth. Many types and sizes are available for purchase to suit the exact purpose of each specific procedure.

For a successful slow-speed burs dental procedure, it is essential to make sure the bur is sharp and the patient’s mouth is prepared beforehand. Doing so requires cleaning the chosen area and administering a topical anesthetic to minimize any possible pain or discomforts. Furthermore, double-checking that the bur is the proper size and shape for the job and set to run at an optimal speed is also prudent.

Slow speed burs dental offer unparalleled accuracy and control during a cutting procedure, resulting in significantly reduced risk of tissue trauma. As a result, slow speed burs dental are often the go-to tool of choice for delicate dental tasks such as cavity drilling or prepping.

Finally, employing slow speed burs for dental applications offers a range of advantages when compared to other methods. These instruments allow dentists to perform different tasks with greater accuracy, not to mention lower likelihood of causing harm to tissue. Moreover, the operation of slow speed burs produces barely any noise or vibration, making them the preferred choice for working in delicate areas of the oral cavity. These reasons render slow speed burs dental a crucial tool in modern-day dentistry.

Related Product

Diamond Bur Ball Round

Product Information Product Name Dental 4-Flute Ball End Mill Brand MSK Model D Number Of BladesZ X N L d 4BTD2060 2 4 6 6 50 3 4BTD2010 2 4 6 10 50 3 4BTD2016 2 4 6 […]

Diamond Coating Round Diamond Cutters

Product Information Origin Tianjing, China Series U Series Brand MSK Cutting Edge Form Helical Structure Ball Diameter (Mm) 3 Material Carbide Minimum Cutting Diameter At Th […]

Step Bur Milling Bur Grinder for Glass Cerami

Product Information Origin Tianjing, China Shank Diameter 1.8 (mm) Brand MSK Scope Of Application CEREC3 Grinding Equipment Material Stainless Steel/Carbide Main Sales Areas […]

Supply Roland DLC Zirconia Burs

Product Information Origin Tianjing, China Series Dental Bur Brand MSK Cutting Edge Form 2 Blade/3 Blade Ball Diameter (Mm) 0.6, 1, 2 Material Very Fine Grained Cemented Car […]

Carbide Roland CAD/CAM Burs

Product Information Origin Tianjing, China Brand MSK Number Of Blades 4 Product Name Dental Special 4-Blade End Mill Model D Number Of Blades Z X N L d 4TD2060HB 2 4 […]

Dental CAD/CAM Milling Burs

Product Information Origin Tianjing, China Material Stainless Steel Brand MSK Applicable Machine Tools A Variety Of Options Custom Processing Yes Whether To Coat No Is It a […]

HP Deburring Carbide Burs

Product Information Brand MSK Material Tungsten Steel Model Grinding Head Custom Processing Yes Feature: The dental grinding head is made of tungsten steel with stabl […]

Post time: 2023-07-31